Monthly Archives: September 2025

Fertilizer Prices

The heat and sunshine are rapidly drying out grain! We have a number of harvest safety resources in this week’s https://cropwatch.unl.edu. Here’s wishing everyone a safe harvest!

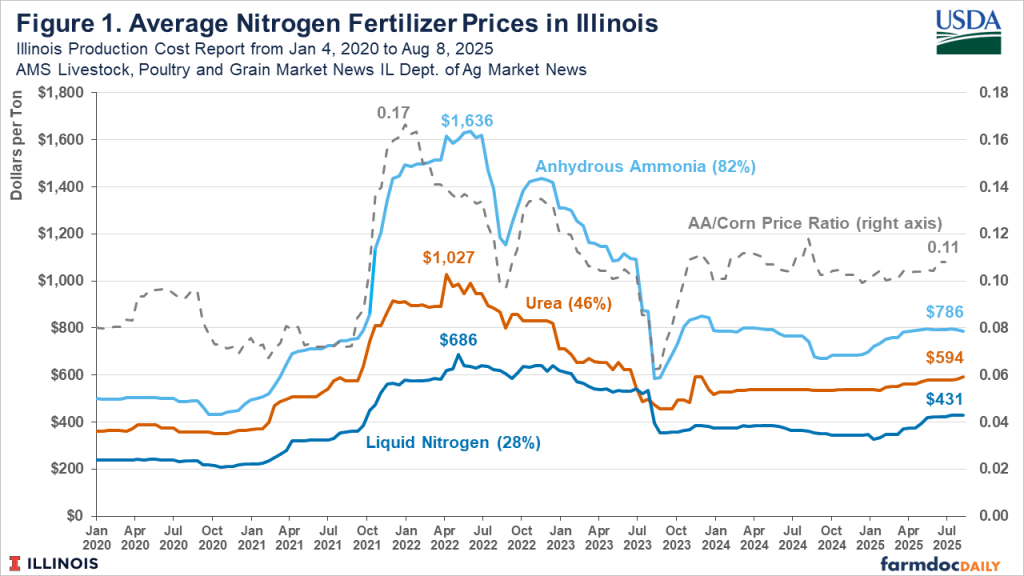

Fertilizer input costs is another topic farmers have been sharing with me about. Farmers will realize the cost of nitrogen inputs are higher than this time last year. An article in Farmdoc Daily from the University of Illinois shares, “Prices in the first week of August averaged $786/ton for anhydrous, $594/ton for urea, and $431/ton for liquid nitrogen. These prices are 6%, 10%, and 20% higher than those reported for the first week of August in 2024….

Relative fertilizer prices provide another important perspective. The ratio of anhydrous to monthly national cash prices for corn reported by the USDA is also included in Figure 1 (right axis). In calculating the ratio, the anhydrous price is converted to dollars per pound of nitrogen based on the average N content of 82%. For example, the latest anhydrous price of $786 per ton is equivalent to $0.48 per pound of nitrogen ($786/(2000*0.82) = $0.48).

The relative price measure (anhydrous to corn price ratio) has followed a similar path to fertilizer price levels since the start of 2020. Relative nitrogen prices peaked at the end of 2021 with a ratio of 0.17. Since the fall of 2023 the ratio has varied around the current level of 0.11. Also similar to absolute prices, the relative price of fertilizer in the past few years has been above longer run averages (average ratio of 0.09 from September 2008 through 2020).”

The authors suggest, “Forward pricing, volume discounts, and varying the timing of purchases and applications are strategies that can be used by farmers to control costs and the risks associated with fertilizer price risk. Farmers are advised to collect pricing information from multiple sources and consider their application rates given the ongoing cost-price squeeze.”

A number of farmers the past few weeks have shared frustration with the input cost prices compared to the crop prices in anticipation of next year’s crop season. Several farmers have asked about how to make their nitrogen more efficient. I don’t claim to have all the answers.

One farmer was looking at numbers and shared frustration over the current fertilizer pricing structure. He looked at where he could be if he became more efficient by 10% over 10 years. Seeing that savings, he asked a question, if farmers in general would become 10-25% more efficient over 10 years, resulting in reduced demand, what would that do to the fertilizer market? And, how could that help with groundwater quality for future generations?

With all these conversations I bring up Sentinel Ag. While no technology is without challenges, based on the research, the main way forward for increasing fertilizer efficiency is to apply less pre-plant nitrogen and use in-season sensing technologies to apply only what the plant needs. That is the point of my Nitrogen Challenge: For farmers with irrigated ground, apply 70-100 lbs N/ac pre-plant. Farmers with non-irrigated ground could apply 50-70 lb N/ac pre-plant. Use a sensing technology like Sentinel Ag to apply the remainder of the in-season nitrogen. There’s options to apply in-season nitrogen via fertigation and also side-dress. I was also asked, “What holds farmers back from using fertigation or from applying nitrogen in-season?” So, that’s a question I will ask you in this one-question poll, and I will share the answers next week: https://app.sli.do/event/bWh8PhzaqsPWRvwweB5YTp.

Using Cover Crops to Help Reduce Other Costs

Fall Armyworms have been around for about 5 weeks now. They’ve really ramped up feeding in pastures, alfalfa, and lawns. Watch fields recently grazed, alfalfa which was recently hayed, and any small grains/cover crops that you are seeding now. Threshold is 3-4 armyworms per square foot but most situations have more. They feed at night and the larger larvae can take out pastures within a day or two. More information at: https://go.unl.edu/oex0.

Using cover crops to reduce other input costs: With an earlier harvest season upon us, tight economics, increasing input costs, and weed resistance issues, the following are considerations for using cover crops to offset and/or reduce other input costs. These considerations come from walking alongside growers who are currently using these practices in their operations at scale and also from research. While adding a cover crop is an additional input cost, look through what I propose below and pencil out the economics for yourself on your own operation. Even if you just try something on one field, it’s worth giving it a try for any of the goals mentioned below.

Forages: Converting some crop ground to annual forages for grazing makes a great deal of economic sense, particularly if you own cattle and crop ground. I will write a separate article on this. For now, rye, triticale, and hairy vetch are options to be considering for spring forage grazing that can be planted yet this fall.

If Planting Soybeans: Goals that fit this consideration: erosion control, weed and disease management. Planting rye this fall or oats in March followed by planting soybeans green into the small grain helps in several ways. First, you can reduce a full PRE-herbicide and only apply the glyphosate at termination time with a residual product if it gets rained or watered in. You should only need 1 POST-herbicide application with a residual product. We have seen rye reduce impacts to soybeans from hail and off-target dicamba. We have seen rye result in no need for a fungicide application for white mold. We have seen oats and rye reduce soybean cyst nematode numbers in fields and reduce sudden death syndrome in fields. There is plenty of research proving how small grains reduce palmer and also soybean diseases.

- For consideration, pencil out removing: Full PRE-herbicide, Second POST-herbicide. With scouting, you can also pencil out removing: Fungicide for white mold. This works best if you plant the soybeans green into the small grain and wait to terminate till closer to flag leaf/boot stage of the small grain.

If Planting Corn: Goals that fit this consideration are: erosion control, weed management, nitrogen from legumes, reducing nitrogen leaching, grazing prior to corn planting. Plant rye, wheat, or winter barley this fall with hairy vetch. Corn can be either planted green into the small grain/vetch mix or the small grain can be terminated pre-plant by glyphosate or clethodim. Don’t use a regular PRE herbicide and allow the vetch to grow till you apply your POST-herbicide that includes an HPPD inhibitor (Callisto-type chemistry to kill the vetch). The vetch will provide nitrogen for the corn crop and an incredible mat for weed control. If one delays corn planting till May 5-15 time-frame, there’s also opportunity to graze the small grain/vetch mix prior to small grain termination and corn planting. While the growers I’ve worked with haven’t observed toxicity from grazing hairy vetch, there are some concerns with this: https://eupdate.agronomy.ksu.edu/article_new/grazing-cover-crops-toxicity-considerations-320.

What one does really depends on the goals. Some are choosing to plant hairy vetch without a small grain to supplement nitrogen. In that case, one needs at least 15 lb/ac vetch seeded preferably in September. If allowed to grow till at least May 10-15 in our area, hairy vetch can provide 50-100 lb nitrogen per acre that we can credit…depending on seeding rate, when it was planted and terminated. Taking a biomass sample next spring will help you determine what potential you have. I highly recommending coupling this with using technology like Sentinel Ag to show when the nitrogen is released to the crop. We had 3 on-farm research studies where corn was planted after hairy vetch in 2025. We don’t have yield results yet, but we did see all three studies show nitrogen release from the vetch around July 2nd. It’s incredible to use tools like this to watch mineralization (or lack of) occur year by year as we just don’t know how to tell this otherwise. Please reach out to me if you’d like to talk through scenarios that may fit your farm goals.

Corn Dry-Down

With harvest ramping up this week, wishing you safety and a good harvest! Make sure to think fire safety and also take care of yourselves emotionally, mentally, and physically. Taking breaks will be important, especially when harvesting this storm-damaged corn, but also because of the stress many are facing.

Watch crop harvest moistures: I mentioned the importance of watching soybean moisture last week and checking soybeans when there’s still some leaves remaining on plants in spite of green stems. We updated this CropWatch article last week https://go.unl.edu/dzb4 and added a table to better visualize what’s being given up in gross by selling soybeans above and under 13% moisture.

Corn is also drying faster than what one may realize, especially after this weekend’s hot temperatures and because of the amount of late-season disease. I’ve been asked what to expect for dry-down for those using storm-damaged corn for high-moisture corn and/or silage. Upon reaching physiological maturity (black layer), most corn hybrids are around 30% moisture. The average corn dry-down for hybrids reaching maturity in late August is around 0.8 percentage point per day and 0.4 percentage point per day for hybrids reaching maturity in mid-September. High heat and wind, such as we experienced last year in September 2024, can lead to well over 1.0 percentage point per day in dry down.

Accelerated senescence and grain drying of corn can also occur with the hail damage and lodging in addition to high amount of late-season southern rust and tar spot this year. One can easily observe hybrid differences in how they’ve reacted to southern rust. Sometimes these pressures lead to premature death of plants including the premature formation of black layer. When that happens, grain drying occurred earlier than anticipated with a higher dry-down rate per day than if the grain had matured normally.

Corn hybrid characteristics can also impact kernel moisture. Hybrids that have thinner or permeable pericarp layers (outermost layer of the corn kernel), are more subject to moisture loss and faster drying rates in the field. I’m unsure how one knows this characteristic though. Other characteristics resulting in quicker dry-down include: lower husk leaf number and thinner husk leaf, how soon the husk leaf tissue turns brown, how well the husk covers the ear (less coverage allows for faster drying), how tight the husk is (as looser husks will increase moisture loss), and how fast the ear turns down vs. remaining upright.

My concern, particularly in the non-irrigated fields, storm damaged stripped up corn, and corn heavily impacted by southern rust in the area I serve, is that corn is actually dryer than one may realize. Apparently this concern also exists in Indiana as Dr. Bob Nielsen, Professor Emeritus from Purdue University, released an article last week on avoiding selling too dry of corn to the elevator: https://www.agry.purdue.edu/ext/corn/news/timeless/WaterShrink.html.

Alfalfa and Wheat Expo: Nebraska Extension is hosting the 2025 Southeast Nebraska Alfalfa & Wheat Expo on Friday, Sept. 19, from 8:30 a.m. to 3:30 p.m. at the Saline County Fairgrounds Office (1600 Tuxedo Park Rd., Crete). This one-day event is designed for wheat and alfalfa producers to gain practical insights, connect with experts, and sharpen their management strategies. Topics include: Equipment considerations for wheat production; Wheat disease updates and management strategies; Insights on achieving high-yield wheat in southeast Nebraska; Alfalfa irrigation, insects, weeds, and crop health management; Pesticide safety updates; Sponsor exhibits, networking, and raffle prizes. Come for the whole day or stop in for the sessions that fit your schedule. Register online at https://go.unl.edu/2025-alfalfa-wheat-expo or call the Saline County Extension office at 402-821-2151.

Harvest Soybean Moisture

What a beautiful September we’ve had thus far! Seed corn harvest has begun and non-irrigated corn is rapidly turning. Soybean harvest will most likely occur by this weekend the way early-season beans are turning.

One note, I’ve noticed droopy ears for several weeks now. It can be due to various environmental X genetic factors such as the high night-time temps coupled with cloudy weather both impacting photosynthesis with specific genetics. I also often observe ear droop to be associated with Fusarium crown rot. Estimated yield losses can be from 12-40% per ear (depending on if the shank pinching occurred during late or early dent stage, respectively). Also, scout fields for shank integrity and seek to prioritize harvest of fields with any increased risk of ear drop.

As we approach soybean harvest, perhaps a frustrating, yet important topic, is seeking to harvest soybeans as close to 13% (the elevator standard) as possible. The frustration is it seems to be such an art and luck in order to do so. For the last several years, it seems that the beans are often drier than what one realizes in spite of green stems and sometimes even leaves remaining on the beans. Test the beans for moisture earlier than you think they may be ready. There’s years like last year when I didn’t even bring this topic up with the hot, dry winds. Hopefully we don’t have a repeat of that.

To avoid beginning harvest when the soybeans are too dry, consider beginning harvest at 14% moisture making combine adjustments and operating at slower speeds as necessary. While there is a dock of around 2.5% for the first 2 points delivering wet beans (the percentage differs by Coops), delivering soybeans much below 13% moisture reduces profits because there’s fewer bushels to sell (load weight divided by 60 lbs/bu assuming 13% moisture). Selling soybeans at 8% moisture, you’re losing about 5.43% yield; at 9% moisture, it’s 4.4%; at 10% moisture, 3.3%; at 11% moisture, 2.25%; and at 12% moisture, it’s 1.14% yield loss. That doesn’t take into account additional risk for shatter losses during harvest. Only 4-5 beans on the ground can add up to a bushel/acre loss due to shatter. The following are profit examples for a field that’s yielding 75 bu/ac:

Example 1. If the grower was to sell beans at 13.8% moisture, he/she could be docked 2.5% of the selling price of $9.60/bu, reducing the actual price to $9.36 per bushel. Total income per acre would be: 75 bu/ac yield x $9.36/bu = $702 per acre gross

Example 2. If the soybeans were harvested at 9% moisture, there would be 3.3 fewer bushels per acre to sell (4.4% of 75 bu/ac yield due to water loss): 75 bu/ac – 3.3 bu/ac =71.7 bu/ac yield x $9.60 = $688.32 per acre gross. In this example it’s better to take a dockage for selling beans at 13.8% moisture than sell them at 9%. The difference is a positive gain of $13.68 per acre or around $1846.80 on a 135 acre field.

Example 3. If the soybeans were harvested at 12% moisture, there would be 0.86 fewer bushels per acre to sell (1.14% of 75 bu/ac due to water loss): 75 bu/ac – 0.86 = 74.14 bu/ac yield X $9.60 = $711.74 per acre gross. If you can’t hit 13%, it’s still pretty profitable to sell them for 12% moisture compared to the other examples.

One more note, we tend to see around 1 day delay in harvest for every 0.1 difference in maturity group. Here’s wishing you a safe and profitable harvest!