Monthly Archives: October 2018

JenREES 10-28-18

Dates are something I tend to remember. This past week I was reflecting on a year ago: fire dangers with three wind events including the Thursday event that was the final straw, a beautiful Wednesday for getting plots out, and then Friday seeing the massive change in yields due to dropped ears. To me, many challenges began with last year’s harvest, and many may wish to forget last year. But reflecting also allows us to learn and count our blessings. Grateful for all the harvest that occurred the past couple of weeks with beautiful weather!…especially since things looked pretty bleak with all the rain and the snow event! Grateful for good yields overall and that we’re not dealing with widespread dropped corn ears at this time!

With the challenges on the soybean side, there’s two

Soybeans showing discoloration from purple seed stain, Phomopsis seed decay, and potential stinkbug damage.

articles in this week’s CropWatch at http://cropwatch.unl.edu that may be of interest. One is about feeding soybeans to cattle. With reports of elevators rejecting soybean loads to the east of our area, we received questions if they could be fed. The Cercospora fungus causing purple seed stain and the Phomopsis fungus causing seed decay do not produce mycotoxins. We’re not aware of any soybean mycotoxins. We also don’t know how these fungi affect soybean seed quality regarding the feed value. So, we recommend testing for that if you’re interested in doing this.

Another article is by Cory Walters, UNL Ag Economist talking about crop insurance help with various dockage that one may have received. This fall’s weather could trigger indemnity payments due to low quality. This is just a short excerpt of his article. He writes, “The following discussion describes how crop insurance adjusts soybean yield due to quality for a particular county. While I have not found any differences in discount factors among counties, it is possible. The final outcome depends upon what the county actuarial documents stipulate. Discount rules contain quite a few if/then statements, so final outcomes will depend upon the particular production characteristics.

…Final yield is determined by multiplying the harvest yield by one minus the sum of all discount factors. Factors for each discount type are summarized as follows:

- A sample grade outcome results in a 3% discount factor so no discount factors for any other grade.

- For test weight, discount factors start at 48 to 48.99 lb with a discount factor of 0.7% that increases to a 1.5% discount factor with a 44 to 44.99 test weight. Test weights lower than 44 are settled through the other category.

- Damage discounts start at 8.01% with a 4.4% discount factor that increase to a 25.2% discount factor with a 34.01% to 35% damage. Just like with test weight, damage over 35% are settled through the other category. Damage includes everything except heat.

- Odor sample grade discounts are 2% for musty odor, 2% for sour odor, and 4% for commercially objectionable foreign odor (COFO).

For example, suppose your harvest soybean sample comes back as grade 4 with a 48.5 lb test weight and 9.4% damage. The field yielded 50 bu/ac. Yield would be reduced by 5.9% from the summation of 0.7% (test weight discount) + 5.2% (damage discount). Final yield would equal 47.05 bu/ac (50 x (1-.007-.052)). An indemnity will be paid if harvest revenue is less than guaranteed, which will vary among producers with different insurance products, coverage levels, and APHs.

Producers with multiple insurable units, likely coming from optional or basic units, should contact their insurance agent to determine the process for keeping samples of each unit. This is very important when soybeans are going to the bin. Quality discounts found here will likely not cover the entire price deduction found at the elevator. While this is unfortunate, some coverage is better than none. It is possible to get discount factors updated and/or modified for upcoming insurance contracts.” For questions and comments please contact Cory Walters at cwalters7@unl.edu and view the entire article in this week’s CropWatch.

Fall Burndown Apps is something we recommend, particularly if you have a problem with marestail or winter annuals like henbit in your fields. Nebraska data has shown over 60% of marestail germinates in the fall. Amit Jhala, Extension Weed Scientist shared an article in this week’s CropWatch. The following is a small excerpt, “Preliminary data for eastern Nebraska suggests that a fall burndown applied with a residual herbicide may eliminate the need for an early spring burndown for marestail control; however, this would not replace an at-planting residual application for management of additional troublesome weed species such as waterhemp and Palmer amaranth. For successful marestail management in the fall, apply herbicides following harvest while weather conditions remain favorable (air temperature above 50°F).

- Glyphosate-resistant marestail is widespread across eastern Nebraska, thus 1 lb a.e. 2,4-D per acre is recommended as the base treatment for marestail burndown.

- Glyphosate or other products such as Sharpen® or Gramoxone® may be tank-mixed with 2,4-D to provide broader spectrum control of winter annuals and certain perennial weeds.

- We generally do not recommend including residual herbicides in fall applications since they provide little benefit in managing weeds that emerge the following spring; however, if infestation of marestail is high in the field and the field has a history of marestail seedbank, it would be advantageous to add a residual herbicide such as Authority® or Valor® or Autumn™ Super, or other metribuzin products.

- Refer to the most recent Guide for Weed, Disease, and Insect Management in Nebraska for more herbicide options.

Fall herbicide application is unlikely to eliminate the need for burndown application at planting. Weeds adapted to cool temperatures, such as marestail, are likely to emerge prior to planting, making it necessary to control them.” He also shows photos in this Week’s CropWatch article of fall tillage or use of rye cover crop as additional options for reducing/suppressing marestail and other winter annual weeds.

2018 York Co. Corn Grower Plot Results

Thank you to Ron and Brad Makovicka for hosting the York County Corn Grower Plot again and for all your efforts with it! Thank you also to all the seed companies who participated!

June 30th wind event affected the tester in the stage of development it was in with greensnap-primarily above or at the ear node. Small ears developed and were included in harvest stand counts.

Rankings were based on adjusted yields (based on a formula for nearest testers) and two decimal places were used to break the tie.

JenREES 10-21-18

Grateful for beautiful weather and harvest progressing again! We got the York County Corn Grower Plot out on Friday and special thank you to Ron and Brad Makovicka for their work and dedication to that effort! I will share the official plot results next week. The York County Corn Grower Banquet will be held on Thursday, November 15 at Chances ‘R in York with social time at 6:30 p.m. and meal at 7:00 p.m. Tickets are only $10 per person for a wonderful meal! Tickets can be obtained from any of the local directors or from the York County Extension Office at (402) 362-5508.Nate Blum from Nebraska LEAD Class 36 will give a presentation on his international tour and there will also be updates from Local, State, and National Corn Directors. For those who estimated yields during the plot tour, you need to be present in order to win the Yeti cooler.

Corn Grower Plot out on Friday and special thank you to Ron and Brad Makovicka for their work and dedication to that effort! I will share the official plot results next week. The York County Corn Grower Banquet will be held on Thursday, November 15 at Chances ‘R in York with social time at 6:30 p.m. and meal at 7:00 p.m. Tickets are only $10 per person for a wonderful meal! Tickets can be obtained from any of the local directors or from the York County Extension Office at (402) 362-5508.Nate Blum from Nebraska LEAD Class 36 will give a presentation on his international tour and there will also be updates from Local, State, and National Corn Directors. For those who estimated yields during the plot tour, you need to be present in order to win the Yeti cooler.

Corn Yields: There’s an interesting article in this week’s CropWatch at http://cropwatch.unl.edu regarding final yield forecasts. Interesting to me are the box plots showing the range of ’30 year average’ vegetative and reproductive stages vs. 2018. The high heat in June shortened the vegetative time-frame. However, the silking through grain fill period was relatively typical for most locations and the long grain fill period with lower temperatures allowed for the better yields we’re experiencing (where drought and late-season hail wasn’t a factor).

Soybean Harvest Losses: Four soybeans in one square foot equals 1 bu/ac harvest loss. Various publications show how to determine harvest losses in areas of 10 to 25 sq. feet. For those with the SoyCorn Pocket Field Guide, page 78 shows estimating loss based on combine header width: http://nebraskasoybeans.org/wp-content/uploads/2017/02/SoyCorn-Field-Guide.pdf.

Evergreen Trees: Some evergreen needles are also changing color right now. It is good to look at your trees to determine the cause of the needle color changes. Evergreen trees actually go through a natural needle drop process with some years resulting in more thinning than others. I think this year may be one of those years as stress events can make needle drop heavier. Needle drop appears as needles turning yellow and falling from the tree. Pine trees may keep their needles for 2-3 or more years while spruce keep theirs for 5-7 years before needle drop occurs. Natural needle drop tends to appear along the main trunk and inside needles of the tree.

I also check for the presence of fungal disease. If the pine tree needles have dark spots/bands on them, it may be a fungal disease like dothistroma needle blight (on Ponderosa and Austrian pines) or brown spot (on scotch pines). The fungi actually kill the needles both directions from the location of the infection. With our heavy rains and high periods of humidity, I’m seeing increased fungal disease in evergreen trees this year. Fungicides applied in mid-May and again in mid to late June can help prevent this.

Pine wilt disease occurs in Scotch and Austrian pines. It’s caused by a bark beetle that has nematodes in its gut. The nematodes are native to Nebraska but Scotch and Austrian pines are not. Ponderosa pines aren’t affected because they’re native to Nebraska. The beetle ‘vomits’ the nematodes into the xylem (water-carrying vessels of the tree). The tree senses the presence of the nematodes and shuts down water to various branches as a way to prevent the nematodes from attacking. Thus why one sees a major branch then side of a tree turning gray-green then yellow-brown. Unfortunately, the entire tree will die typically within 3-9 months. Some farmers have tried trunk injections and drenches around their trees in hopes of saving them, to no avail.

On spruce trees, I’m seeing yellow/purple/browning of needles. This often is due to a fungal disease called rhizosphaera needle cast. One way to determine if this is the culprit is to look for tiny black dots on the gray twigs next to affected needles. The black dots are actually fungal structures that allow for infection to occur. Fungicide applied in May and after heavy rains can help. I always intend to spray my spruce tree each May but have failed to get it done the past several years. With recent rains, I’m trying it this fall to see if it can help; will let you know!

There have been several calls about arborvitae rapidly turning brown and I’m seeing evidence of heavy spidermite pressure at one time. Spruce spidermites affect spruce, juniper, arborvitae, etc. The rains and snow washed them off, which is one way to manage them. Evidence can be stippling (tiny yellow-green dots on needles) and also using a magnifying glass, one may see some webbing on undersides of needles. One can also just bang the needles on a white piece of paper to see if any mites are still active. Mites are most active in the cooler times of the season…so August through October in this case. Great resources for additional information include: Diseases of Evergreen Trees and Insect Pests of Evergreen Trees which can be obtained here: https://nfs.unl.edu/publications.

The dark spots/bands observed on these needles are indicative of fungal disease (dothistroma needle blight on Austrian and Ponderosa pines) and (brown spot on Scotch pines). The fungus kills the needle both directions from where infection occurs creating needles that are often part green to yellow-brown eventually becoming yellow-brown.

When Evergreen Doesn’t Mean Ever Green

Great info and thoughts from Elizabeth on the reasons why evergreens aren’t always staying green in the fall.

Autumn is officially here; cue the falling leaves, cool nights, and yellowing pine trees. Knowing the cause of the discolored needles will help to know if it is nature taking its course or if it is a disease infecting your trees.

View original post 709 more words

Grain Observations

This post shares observations of what I’ve been seeing in fields pre-harvest and during harvest during this 2018 growing season. Some of these problems stemmed from hail/wind damage and others insect damage. This is a longer post with the desire to have many resources available to you in one place. Hopefully this will be helpful for diagnosing concerns as harvest continues.

Soybean Observations

(Photos above) Hail-damaged soybeans pre-harvest. The plants in this field weren’t pummeled into the ground, but from the road it was deceiving as to what the soybeans were actually like on these plants. The two smaller photos are all the soybeans found on 2 adjacent plants from the top soybean photo pre-harvest. There were a lot of aborted pods on stems and moldy beans in general. For those who combined hail damaged beans in the area, farmers shared they had everything from ‘lima’ beans to shriveled, moldy beans as you can see in these pics, which is also what we were anticipating may be found.

Examples of soybeans that had sprouted in the pod pre-harvest. We may unfortunately see a lot more of this with additional rains.

Removed a bunch of pods from a plant with Diaporthe/Phomopsis complex in which there were many flat, unfilled pods and pods of various stages of fill. This is what I found in the pods. This complex consists of diseases such as Pod and Stem Blight, Stem Canker, and Phomopsis Seed Decay. Perhaps note which varieties you notice more of this.

Two different grain quality concerns in soybean. (Left photo) This soybean damage can be attributed to potentially a few things. I have found pycnidia of Phomopsis (Phomopsis seed decay) in samples like this. The UNL Plant and Pest Diagnostic Clinic has also diagnosed Phomopsis Seed Decay in samples. There’s also a publication from Ohio State (https://agcrops.osu.edu/newsletter/corn-newsletter/2017-24/stink-bugs-soybean) which attributes these symptoms to stink bugs. There was stink bug pressure in some fields this past year. So there’s potential that we have a few things occurring creating these symptoms. (Right photo) This soybean damage is called ‘Purple Seed Stain’ and is caused by the fungus Cercospora kikuchii. I mentioned this in this blog post.

Corn Observations

Pre-harvest was seeing quite a bit of Fusarium in places where hail stones or insect damage occurred on ears such as this photo. Notice at the base of the ear, the ‘starburst’ shape occurring within kernels (I think of it like fireworks exploding when viewing the top of the kernel). Kernels infected with Fusarium will have a white/pink fungal growth that later causes kernels to become brown or gray and shriveled.

This ear was from the same hail-damaged field as photo above and I picked this right before the field was harvested. The Fusarium and picnic beetles had greatly destroyed affected kernels. Cladosporium (green colored fungus) can also be seen affecting this ear where damage had occurred.

Cladosporium ear and kernel rot seen on kernels already affected by Fusarium, particularly in hail damaged fields. This is a lesser ear rot fungi and doesn’t produce a mycotoxin but can create increased damage to kernels. Was recommending taking grain damaged to this extent directly to the elevator.

The deep red color on this hail damaged ear is due to Gibberella. We may see an increase in this with all this late-season rain. Other symptoms include matted fungal growth with husks sticking to ears. Gibberella has the potential to produce the mycotoxin zearalenone. The presence of the fungus DOES NOT automatically mean the presence of a mycotoxin.

Kernels at harvest displaying damage from Fusarium and Gibberella. I received a number of samples from various farmers displaying these symptoms and picked out these kernels to show. Notice the pink/red discoloration of the kernel and also the shrunken, damaged kernels that are brown or gray in color. Grain should be dried as quickly as possible to 15% moisture to cease fungal growth in storage.

This is another field I’ve been watching that was hail damaged. The ears themselves show very little damage; however, my concern is the ‘starburst’ pattern occurring throughout these ears throughout the field. The ‘starburst’ pattern is also characterized by the white lines observed on the sides of individual kernels. This is caused by Fusarium.

The above photo is that same field at harvest. ‘Starburst’ pattern on kernels seen as white streaking due to Fusarium. More severely infected kernels are brown in color and dissecting them show they were trying to germinate. Also noticing cob rot occurring. Drying the grain to 15% moisture as quickly as possible will cease fungal growth. Fusarium also has the potential to produce the mycotoxins Fumonisin and Deoxynivalenol (also known as DON or Vomitoxin). NOTE: The presence of the fungus DOES NOT automatically mean the presence of a mycotoxin.

Photos above shared by a Clay County farmer who observed kernel germination and Fusarium growth (mostly due to western bean cutworm damage) upon harvesting his field. Hormonal balance within the kernels shifts towards harvest. At full maturity, very little abscisic acid (ABA) is left in the kernel (in both corn and soybeans) which allows them to germinate in correct conditions after harvest. These conditions include moisture and temperatures above 50ºF. Presence of fungi such as Fusarium and Gibberella also increases gibberellins in the kernels allowing for kernel germination with presence of moisture as we’re seeing this harvest. Increasing air flow during harvest will hopefully blow most of these damaged kernels out the back of the combine.

- Corn Ear Rots, Storage Molds, Mycotoxins, and Animal Health, ISU, 1997. (Nice comprehensive resource available in PDF download via web search)

- UNL Corn Disease Profile III: Ear Rots

Grain Storage

There’s over 25 species of fungi that can produce ear molds with the majority of them ceasing growth at 15% moisture within the kernel. Thus, we recommend drying grain to 15% moisture as quickly as possible to cease additional fungal growth within the grain bin. The table below shares the days required to dry corn to 15% moisture with 1.0 cfm/bu and various temperature and humidity conditions.

“Since drying time is directly proportional to the airflow, the producer can calculate the estimated drying times when using airflows other than 1.0 cubic foot of air per minute per bushel (cfm/bu). For example: Table II shows when drying corn from 18 percent to 15 percent moisture with 50F and 50% relative humidity air, the estimated drying time is 12.5 days using a 1.0 cfm/bu airflow. If the airflow is 1.25 cfm/bu, the estimated drying time would be 12.5 days / 1.25 = 10 days. For 1.5 cfm/bu, the drying time would be 12.5 days / 1.5 = 8.3 days. For 0.8 cfm/bu, the drying time would be 12.5 days / 0.8 = 15.6 days.” Source: Management of in-bin natural air grain drying systems to minimize energy cost.

- Management of in-bin natural air grain drying systems to minimize energy cost

- Grain storage management to reduce mold and mycotoxins (ppt presentation)

- UNL CropWatch Grain Storage Resources

- Managing large grain bins for potential mycotoxin contamination

Mycotoxin Information

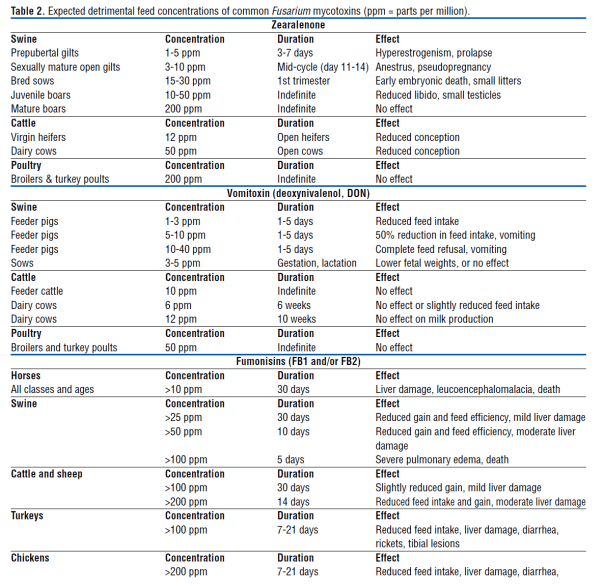

In 2018, we’re primarily seeing Fusarium and Gibberella species which have the potential to produce mycotoxins. Thus, the information below is directed at those fungal species and mycotoxin levels that can be associated with them. Again, the presence of fungi does not automatically mean a mycotoxin is present.

The following toxins can be produced from species of Fusarium and Gibberella. Source: Corn Ear Rots, Storage Molds, Mycotoxins, and Animal Health, Iowa State publication, 1997.

Source: Corn Ear Rots, Storage Molds, Mycotoxins, and Animal Health, Iowa State publication, 1997.

- Grain storage management to reduce mold and mycotoxins (ppt presentation)

- UNL CropWatch Grain Storage Resources

- Managing large grain bins for potential mycotoxin contamination

- Understanding Fungal Toxins UNL

- Sampling and Analyzing Feed for Toxins UNL

- Use of Feed Contaminated with Fungal Toxins UNL

- Feeding Storm Damaged Corn: A few thoughts from a Veterinarian

Also, there’s a new app called “Mycotoxins” and it’s another resource with ear rot pictures and mycotoxin information put out by several Universities produced for both Apple and Android devices.

JenREES 10-7-18

Grateful for the crops that have been harvested thus far! Also grateful for so many paying attention to grain quality coming out of the fields! That’s been a large part of the past 10 days for me…obtaining grain samples and pictures to answer grain quality questions from quite an area. So I did a quick literature review to better understand the conditions when various ear rot fungi grow and also put together a blog post to hopefully help all of us better diagnose what we’re seeing in grain samples-whether corn or soybean. You can find it at: https://jenreesources.com/2018/10/08/grain-observations/.

Fungal growth in storage is based on moisture, humidity, and temperature. I’ve heard various numbers being used for grain storage and I’m not a grain storage expert. I can also appreciate it costs you more and takes time with the current weather conditions to dry corn. In general, most Extension publications throughout the U.S. recommend getting grain dried to 15% as quickly as possible and maintaining grain in long-term storage at 13%. Briefly, in looking through the literature, the reason for this advice is because various ear rot fungi can continue to grow on and inside those kernels. There’s over 25 species of ear rot fungi with most of them ceasing growth at 15%. The main exception is Aspergillus which has species that can continue from just below 13 to above 14%. Thankfully we don’t have a problem with Aspergillus this year. We are seeing a lot of Fusarium and some Gibberella (which may increase with this rain). But we’re also seeing some Diplodia and other lesser ear rot fungi such as Penicillium, Cladosporium, and Nigrospora. The thing is that each fungal species has a temperature and moisture range in which they continue to grow. So if one is growing in a kernel, it gives off heat and moisture allowing for changes in temperature, humidity, and moisture within that area which can allow for other fungal species to grow. Fungi grow from one infected kernel to adjacent kernels. Having more ‘fines’, cob pieces, etc. can increase potential for fungal growth in the bin. Insects also give off heat which changes localized dynamics. Because of these reasons, our recommendation is to get grain dried to 15% as quickly as possible to help stop fungal growth we’re experiencing this year, particularly from Fusarium species. We’re not saying you need to get the grain dried to 13% immediately. It’s only a consideration down the road if you’re storing the grain till next summer. The following NebGuide is a great resource: Management of In-Bin Natural Air Grain Drying Systems to Minimize Energy Costs: http://extensionpublications.unl.edu/assets/pdf/ec710.pdf. Our grain storage resource page can be found at: https://cropwatch.unl.edu/grain-storage-management.

Also, there’s a new app called “Mycotoxins” and it’s another resource with ear rot pictures and mycotoxin information put out by several Universities produced for both Apple and Android devices.

Farm/Ranch Transition When You Aren’t in Control Nov. 14 York: Passing the farm/ranch on to the next generation is a tough job, especially if the next generation is unsure of what will happen when their parents pass. It is especially for those people, who are wondering what is going on, that a series of farm and ranch transition workshops are planned at Valentine, Ainsworth, O’Neill, Norfolk and York from Oct. 23 to Nov. 14.

The workshops will focus on the needs of the “sandwich generation” between parents who still own land and children who might want to join the operation, on whom farm/ranch transition and transfer often falls. Lack of communication often hinders transitions. The Gen2, or Sandwich Generation, will learn how to communicate with family to understand the transition and practice asking difficult questions.

Legal topics presented at the workshops will center around Gen2 needs, including elements of a good business entity, levels of layers for on-farm heirs control and access, and turning agreements into effective written leases. Joe Hawbaker, estate planning attorney, and Allan Vyhnalek, Nebraska Extension transition specialist, will share stories and experiences to successfully plan on the legal side. Dave Goeller, financial and transition specialist, will cover financial considerations, retirement, and compensation versus contribution.

Many families struggle to split assets fairly between on-ranch and off-ranch heirs, while continuing the ranch as a business. Goeller will discuss the family side and what to consider when dividing assets. Vyhnalek will also cover less-than-ideal situations, negotiating, and looking for other business options. The times are 9 a.m.-4:30 p.m. at each location. The closest location to this area is November 14 in York at the 4-H Building. Cost is $20 per person. If more than two people are attending per operation, the cost is $15/person. Pre-register at (402) 362-5508 or jrees2@unl.edu for meal count.

Funding for this project was provided by the North Central Extension Risk Management Education Center, the USDA National Institute of Food and Agriculture Award Number 2015-49200-24226.