Blog Archives

JenREES 1-6-19

It feels like a long time since I wrote! Being burned out, I wasn’t ready to reflect on 2018 in my previous column. Perhaps some of you felt that way too? There were plenty of challenges for agriculture in 2018. Grateful for breaks. Grateful for a new year! Grateful for good new hires in Extension to help with the work load throughout the State! As I reflect on the past several years, thank you for your support as I’ve done my best to cover a lot of counties to the best of my ability. Grateful for the opportunity to serve Nebraskans via Extension and to enjoy this work! And while it comes at the expense of our farmers, I’m grateful for the continual opportunity to learn with every new crop/pest problem. I know a few of you have wished these problems didn’t have to happen to you so I could learn! Yet I do appreciate the phone calls to work through situations with our farmers and ag industry professionals. While each year presents unique challenges, I’m always inspired by the resiliency of our farmers and those in the ag community. Looking forward to serving you in 2019!

Short Survey: In Extension, we always need to prove that what we do in our work brings value to those of you we serve. Would you please consider completing this short survey for me to provide feedback, specifically regarding my email newsletter, news column, any specific way I helped you last year, and ways I can improve in my Extension role in 2019? All feedback is anonymous. Please go to the following direct link: https://app2.sli.do/event/q2p1sedv/polls or you can also go to https://www.sli.do/ and enter the code 7708. Thank you for considering this!

York Ag Expo: Reminder of the York Ag Expo this week! Hoping to see many people come out to view the exhibits and also come to the educational sessions. I try to train people to RSVP for all my educational events, but walk-ins are always welcome. Chemigation is on January 9th from 9 a.m.-Noon with Steve Melvin. Then come out and hear the latest on the Farm Bill, Crop Insurance decisions, and Farm Taxes from 1-4 p.m. from Brad Lubben, Cory Walters, and Austin Duerfeldt. On January 10th, I will present private pesticide training from 9 a.m.-Noon. Then come out for residue and manure management from 1-4 p.m. with Mary Drewnoski, Michael Sindelar, Tim Mundorf, and myself. From 4-5 p.m. will be the keynote speaker Chad E. Colby. Agribusiness after-hours from 5-6 p.m. Ag appreciation lunch both days and all exhibitors and sponsors can be found at: https://yorkchamber.org/event/ag-expo/. Hope to see you there!

RUP Dicamba Training: On the Nebraska Department of Ag website, you will now see the list of UNL face-to-face trainings, the link to the UNL online dicamba training, and a list of certified applicators who have completed dicamba training. I took the online course on Friday so I could better answer questions. This year, it allows you to take one of two tracks: presentations by Dr. Bob Klein or Dr. Greg Kruger. You are also welcome to take both for more information. There are instructions with screenshots on the online dicamba training webpage: https://pested.unl.edu/dicamba-training-instructions. Some reminders regarding this, the applicator’s name and applicator ID number need to be listed when registering for the online course. Last year we had some wives complete the registration for husbands and then the wives were listed as certified and not the husbands. This year anyone applying RUP dicamba must complete approved RUP dicamba training and must also be a certified licensed pesticide applicator. Regarding face to face trainings, I am not having a dicamba training during the York AgExpo, but there are many options available that can be viewed on the NDA website. For that training, you will need to bring your certified applicator number. If you are a new pesticide applicator who hasn’t received a number yet, you will put ‘pending’.

York-Hamilton Cattlemen’s Banquet: The York-Hamilton County Cattlemen are planning their 71ST Annual Cattlemen’s Banquet for Tuesday January 29, 2019 at the Holthus Convention Center in York. Dave Thorell of Loomis, NE will be the featured entertainment. Dave Thorell is a regionally known speaker, avid agriculture advocate, humorist, story teller and was the voice of Agriculture News for over forty years on KRVN Radio. Thorell was elected into the Nebraska Broadcaster Hall of Fame. The Cattlemen will also recognize Rich Pearson of Hordville and Allen Roehrs of Bradshaw as Honored Guests for the evening for their contributions to the area livestock industry and the Cattlemen’s Association. The evening starts at 6:30 with social time, a Prime Rib meal at 7:00 with entertainment and recognition of honored guests to follow. Cattlemen’s Banquet tickets are $25 per person. Sponsorships are also available that include two banquet tickets and recognition at the banquet for $150. Cattlemen’s Banquet tickets can be purchased from any of the York-Hamilton County Cattlemen’s Directors including Brian Blase of Hordville; Brock Ekhoff and Terry Ross of Aurora; Jeff Underwood of Exeter; Allen Klute and Mark Klute of Hampton; David McDonald of Phillips, Jeff Meradith, Kim Regier and Josh Chrisman of York; Kim Siebert of Henderson, plus the Extension Offices in York County and Hamilton County.

JenREES 12-23-18

Wishing everyone a wonderful Christmas and time to celebrate this special time of year with family and friends!

With the re-registration of the restricted use pesticide (RUP) dicamba products, I’ve been receiving questions regarding the training and label requirements. Dr. Rodrigo Werle who is now a weed scientist in Wisconsin put together a really nice blog post to help understand the new buffer label requirements at: http://www.wiscweeds.info/post/dicamba-buffer-requirements/.

RUP dicamba training can be obtained at the Crop Production Clinics (CPC), Nebraska Crop Management Conference (NCMC), Approved Industry Trainings, Extension Trainings, and via an online course. It is not built into our private applicator pesticide training, but many of us are offering it as an option on the same day and at the same location as pesticide training. There is no charge for dicamba training (unless you’re taking it at a program that requires a fee such as CPC and NCMC). You have to be a certified pesticide applicator to apply RUP dicamba this year and you need to provide your applicator number for dicamba training.

All information from the Nebraska Department of Ag including labels, best management practices, list of trainings and list of certified applicators who’ve taken the training, can be found at: http://www.nda.nebraska.gov/pesticide/dicamba.html. The online dicamba training (available after January 1, 2019) and additional informational resources from UNL can be found at: https://pested.unl.edu/dicamba.

I’ve been thinking about these dicamba buffer requirements in addition to how heavy palmer and other weeds often are on our endrows. Research shows that palmer is sensitive to red and natural light in triggering germination. Research and observation have shown incorporation of a small grain helps with reducing palmer amaranth germination early in the season, and if taken to grain, delays germination till after harvest of the small grain. Chris Proctor, Extension Educator, and I were talking and wondered if we should consider incorporating a small grain into our endrows (especially in soybean fields) or possibly even perennial grasses for situations that would be a better fit? I’m unsure how practical this is for every farmer or every situation, but in floating the idea with farmers as I’ve presented about palmer, it seems like it may work for some. We’ve seen from previous years the challenges with weather in being able to spray dicamba and herbicides in general. With the buffer requirements and the fact that endrows often have heavier weed pressure, I just wonder if we need to start looking at treating endrows differently. Would like to hear your thoughts on this and/or other ideas!

We also know from research at the University in Arkansas in greenhouse studies that palmer only took three generations to become resistant to dicamba. Considering three generations, it’s like saying dicamba is applied to soybean one year, corn the next year, and soybean again the following year with year 4 showing resistance developing. Dicamba is a great tool in our toolbox and palmer is perhaps our most difficult weed to control right now. Consider choosing which crops you will use dicamba on this next growing season and think through the next few years’ crop rotation and herbicide program on your different farms to help with selection pressure and resistance management.

- Jan. 21: York County, 5 p.m., 4-H Bldg, York

- Jan. 22: Thayer County, 5:30 p.m., Community Center, Davenport

- Feb. 5: Merrick County, 10:00 a.m., Fairgrounds, Central City

- Feb. 6: Hamilton County, 10:00 a.m., Fairgrounds, Aurora

- Feb. 7: Seward County, 11:30 a.m., Civic Center, Seward

- Feb. 12: Kearney County, 12:00 p.m., Fairgrounds, Minden

- Feb. 14: Webster County, 12:00 p.m., Community Center, Blue Hill

- Feb. 19: Franklin County, 1:30 p.m., Fairgrounds, Franklin

- Feb. 20: Clay County, 2:00 p.m., Fairgrounds, Clay Center

- Feb. 28: Nuckolls County, 10:00 a.m., Community Center, Nelson

- Mar. 5: Hamilton County, 10:00 a.m., Fairgrounds Aurora,

- Mar. 11: Adams County, 4:00 p.m., Fairgrounds, Hastings

- Mar. 12: Jefferson County, 10:00 a.m., Fairgrounds, Fairbury

- Mar. 13: Gage County, 10:00 a.m., Extension Office, Beatrice

- Mar. 14: Saline County, 10:00 a.m., Extension Office, Wilber

JenREES 11-4-18

Last week I had the opportunity to attend and speak at the Weed Science School. It was an interesting day of learning, discussion, even reflection. Dr. Amit Jhala, Weed Science Specialist, did a really nice job of organizing the day and creating opportunities to hear from University, Industry, and Nebraska Dept. of Ag (NDA) speakers in addition to providing hands-on activities. While dicamba was a topic that was discussed, we didn’t hear about EPA’s ruling till the following day that the RUP products for soybean will be re-registered. Tim Creger with NDA shared that 6 other dicamba products, most with pre-mixes, will be registered this year. He also shared there are 40 ag labeled dicamba products that are not restricted use pesticides, and as long as they aren’t registered for soybean use, he doesn’t anticipate they will become restricted use pesticides. Comparing NDA claims from 2017 to 2018, they received 95 claims (24 investigated due to lack of resources) in 2017 compared to 106 (50 investigated but only 31 resulted in full investigations due to desire of the person filing the complaint) in 2018. Of the 106 claims in 2018, 17 were non-ag related.

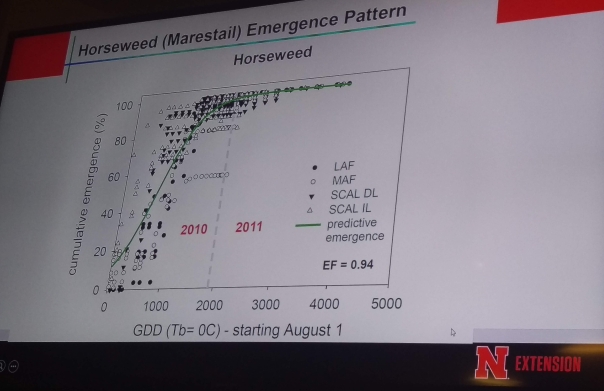

In last week’s column, in sharing about fall burndown apps, I had mentioned that 60% of marestail (horseweed) in Nebraska germinated in the fall. An updated number of 90-95% fall germination for Eastern Nebraska was shared. This once again emphasizes the importance of considering fall apps for fields with marestail pressure.

marestail (horseweed) in Nebraska germinated in the fall. An updated number of 90-95% fall germination for Eastern Nebraska was shared. This once again emphasizes the importance of considering fall apps for fields with marestail pressure.

Dr. Kevin Bradley from University of Missouri shared on 7 points he’s learned from 15 years of researching waterhemp. They included: Never underestimate waterhemp (I’d say the same for palmer); Era of simple, convenient, quick control is over; Use full herbicide rates and pre-emergence herbicides with residual; Overlap pre + post applications (which we also see with palmer-put that post on a week earlier than you think you need it); Glufosinate, dicamba, and 2,4-D may work now but they’re tools being abused; New traits won’t solve the problem; and Get rid of herbicide-centric way of thinking-we need an integrated approach. He thought he was sharing something shocking in that last statement, but I’d say several of us seek an integrated system’s approach to what we do, including weed management. So ultimately, herbicides aren’t the answer for weed control and we need to be thinking about management from a system’s perspective including crop rotation, use of cover crops, residue management, seed destruction, etc. Especially as from the industry perspective presented, it takes an average of 12 years and average investment of $250 million for a new chemistry to be developed. They are seeking chemistries now that work on specific sites of action (how targets within plant) within the mode of action (specific group or chemistry number).

On November 14th, we’re hosting a Farm/Ranch Transition workshop at the 4-H building in York. This is the closest location for our area. The workshop will focus on the needs of the “sandwich generation” between parents who still own land and children who might want to join the operation, on whom farm/ranch transition and transfer often falls. The Gen2, or Sandwich Generation, will learn how to communicate with family to understand the transition and practice asking difficult questions. Legal topics will include elements of a good business entity, levels of layers for on-farm heirs control and access, and turning agreements into effective written leases. Joe Hawbaker, estate planning attorney, and Allan Vyhnalek, Nebraska Extension transition specialist, will share stories and experiences to successfully plan on the legal side. Dave Goeller, financial and transition specialist, will cover financial considerations, retirement, and compensation versus contribution. Cost is $20 per person. If more than two people are attending per operation, the cost is $15/person. Pre-register at (402) 362-5508 or jrees2@unl.edu for meal count. Funding for this project was provided by the North Central Extension Risk Management Education Center, the USDA National Institute of Food and Agriculture Award Number 2015-49200-24226.

November 15th is the York County Corn Grower Banquet at Chances ‘R in York. Social time begins at 6:30 p.m. with a wonderful meal at 7:00 p.m. We will hear from Nate Blum, LEAD 36, on his international trip. We will also hear from local and state directors. Tickets are only $10 and can be obtained from any of the local Corn Grower directors or from the Extension Office at (402) 362-5508. The winner of the Yeti cooler from guessing plot yields will be announced, and those who guessed need to be present in order to have a chance to win. Plot results can be obtained from the Extension Office. Hope to see you there for a nice evening with a wonderful meal to hopefully celebrate the end of harvest season!

JenREES 8-12-18

Crop Update: I’m so sorry to all affected by Monday night’s hail/wind storms! For those reading this before Monday, a reminder of hail damage meetings we’re having Monday Morning, 10 a.m. at the Utica Auditorium and Monday Afternoon, 1:30 p.m. at the Fairgrounds in Central City. I will post key points of what’s discussed at http://jenreesources.com after the meetings. Please also check out our Hail Know Website at https://cropwatch.unl.edu/hailknow and take the survey on the page to help us better know how to serve you with that resource.

This week’s CropWatch at http://cropwatch.unl.edu shares two different dicamba-related articles. One is a case study to walk through the forensic analysis for off-target dicamba movement showing how it originated from a corn field. The other goes into more detail regarding soybean still producing a new node every 3.7 days upon off-target dicamba movement (as long as the apical meristem has not been killed). It’s truly a significant piece of information, because without it, the assumptions within the forensic analysis don’t work!

Also, you have an opportunity to share your voice and input. This past week we’ve heard that EPA is planning to make their decision by mid-August on whether or not to extend registrations of XtendiMax®, Engenia®, and FeXapan® in order to help inform the seed and chemical industry for next year’s purchases. Some of you have called or talked with me about this. A few have understandably been pretty upset that these products are getting so much blame when, in this part of the State, much off-target dicamba movement starts from corn applications. That doesn’t get as much press nationally. While I’ve tried hard to share the story here and am grateful to our media partners who have helped me, I’m one very small voice. I have no idea what will happen; my concern is the bigger picture-potentially losing dicamba period as a tool in our toolbox.

So you have an opportunity to share your voice in Nebraska Extension’s survey that will be shared with the EPA: https://www.surveymonkey.com/r/JWDCY3C. Share your opinion on Xtend technology. Share your opinion on where you’ve discovered off-target movement from in 2017 and 2018. Share your opinion on dicamba. The results will also be compiled and shared on CropWatch and winter meetings. Thank you for considering this!

Aphids and Frogeye: I’ve also received a handful of questions regarding corn leaf aphids in corn and frogeye leaf spot in soybean. Both have rapidly increased in some corn and soybean fields. At beginning dent and various stages of starch-fill corn, I just have a hard time putting anything else into this crop. So I haven’t been recommending insecticides and there’s no thresholds this late to support it. In fields I checked from last week to this week with corn leaf and bird cherry oat aphids, I’ve also seen an explosion of beneficial insects and mummification occurring of aphids, which is helpful. Regarding frogeye, it’s one where we recommend a product containing a high amount of strobilurin at R3 or R5. Many beans are at R6 or almost there, so again, I’m having a hard time putting any more money into this. High humidity and leaf wetness for 12 hours or more will rapidly increase frogeye, so the worst situations I’ve seen through the years are in gravity-irrigated fields. Also, seeing a number of soybean defoliators in fields. Please check out this CropWatch article at: https://cropwatch.unl.edu/2018/soybean-defoliators to better help understand how much defoliation can occur in soybean.

Lawn Renovation: For those seeking to improve your lawn or get one established, August is a great time to do so! I really like this resource for this purpose: https://go.unl.edu/rz9z. If you’d prefer to watch videos, Backyard Farmer has a series of Lawn Renovation videos, but this link gets you to the most recent one regarding fall renovation: https://youtu.be/Fxd1NUQ8ScQ.

JenREES 8-5-18

Thank you to all who made the York County Fair go so smoothly! It’s always a joy to see the 4-H and FFA youth and families rewarded for the hard work they put into their projects!

Crop Update: I didn’t get out to the field much this week with fair but did spend a few

Bird cherry oat aphids on ear husks and green leaf aphids on leaves of plants in this non-irrigated field. Lady beetle larvae predators also present.

hours one afternoon. There are portions of the area I serve that have been blessed with rains and look really good. The main thing that I’m seeing a lot more of this week is aphids in corn fields. This can be common in fields where fungicide is applied as the fungicide kills a beneficial fungus that attacks aphids. Some aphid species are also attracted to moisture stressed crops. The heat has also pushed the crop along quickly. We have another yield forecasting article in this week’s CropWatch at http://cropwatch.unl.edu where we talk about the impact of the heat on yields. As of right now, based on comparing this year to 30 years of weather data, it’s appearing corn may reach maturity 1-3 weeks early. Irrigated yields are estimated to be near average and above to near average for non-irrigated corn (where drought is not a factor). These yield forecasts are based on simulations under ‘perfect conditions’ (with no nutrient loss, disease etc.) but they can give us an indication of what may happen if we continue with higher heat conditions.

Unfortunately, pockets in the area continue to miss rains. The drought monitor still is not

Drought-stressed soybean field.

reflecting the drought in this part of the State; at this point, I’m unsure what else either Al Dutcher or I can do about this. One farmer reminded me drought occurred in the same area in 2006, 2012, and now 2018-six years apart each time. Driving the area, hardest drought-stressed crops really took a turn this past week with corn in hard dough to early dent with some kernel abortion and soybeans are beginning to abort pods and quit filling seeds. One question has been on weighing taking corn for silage or not. If you have at least an estimated 50 bu/ac grain in most of the field other than highly compacted areas, it may be more profitable to keep for grain (unless you’re looking for cattle feed). The following are some resources to consider further:

- July 2018 BeefWatch article on considerations for green chop/silage for cattle feed, include best management practices, etc.: https://go.unl.edu/e3y5

- July 2018 K-State article for considerations on taking corn for silage or grain: https://enewsletters.k-state.edu/beeftips/2018/07/02/considerations-for-use-of-drought-stressed-corn-for-cattle/

- All UNL Drought Resources: http://droughtresources.unl.edu

Dicamba: We’ve often mentioned the research showing a soybean plant producing a new node every 3.7 days upon reaching V1 stage. And, I’ve used that in the forensics assessment for determining a timing for off-target dicamba movement. One question I’ve had was “Do soybean plants continue to produce a new node every 3.7 days upon being affected by off-target dicamba?” My assumption in the forensic analysis I have used is that a new node continued to be produced every 3.7 days in spite of off-target dicamba. However, the only way to really test this would be to have the same soybean variety in both an Xtend and non-Xtend version. We will release a CropWatch article next week in which a situation like this occurred at the Eastern NE Research and Extension Center. Dr. Jim Specht counted nodes in both the non-Xtend variety with off-target dicamba and the Xtend variety that wasn’t affected. He found the same number of nodes in spite of the dicamba affected non-Xtend variety being shorter in height and having less canopy. So that in itself is good information for use in forensic assessments. However, he also found plants in which a higher off-target dicamba dose affected the top-most growing point. When that occurred, the number of nodes was affected.

Last year, a group of us released a dicamba survey during Soybean Management Field Days. Reminder those are upcoming this week (https://enre.unl.edu/soydays)! The survey helps us understand your perspectives about dicamba and this year we’ve added questions regarding using Xtend technology. Hopefully it will provide helpful information for all of us and the results will be shared via CropWatch and winter meetings. We’d encourage and be grateful for any soybean growers to participate at: https://www.surveymonkey.com/r/JWDCY3C.

South Central Ag Lab Field Day: Please hold August 29, 2018 for UNL’s South Central Ag Lab (SCAL) Field Day near Clay Center! Attendees can choose which sessions you would like to attend. Options include the latest SCAL research in the areas of Irrigation/Water Use; Nutrient Management; Weed, Disease, and Insect Management; Cover Crops; and Cropping Systems. CCA credits will be available and there’s no charge to attend. Will have more specifics for you next week but please hold the date for now!

Vine Crop Problems: The following resource explains options for diagnosing various problems with cucumbers, squash, and melons: https://hortnews.extension.iastate.edu/2011/8-24/cucurbitwilt.html.

JenREES 7-22-18

Crop Update: This past week was fairly interesting with southern rust being confirmed in a few Fillmore, Thayer, and Saunders County fields. We would recommend to continue scouting fields as the disease was low incidence at all these sites. There also were a number of questions regarding fungicide applications.

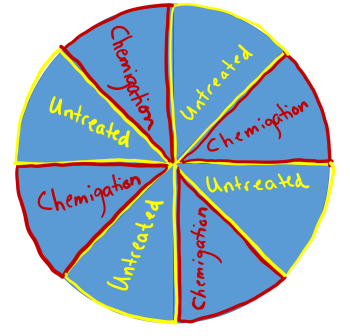

For those asking about chemigating fungicides, it’s important to ensure the fungicide

On-Farm Research design for those considering chemigation vs. none of fungicide (could also use this for 2 different irrigation amounts instead). Can have more pies than this for smaller area if desired-we would just need at least 4-5 pies of each of same area. Data can be collected throughout field normally during harvest via yield monitor and we can use software to determine yields within the pies as long as we know the angle degrees you used.

product label allows for chemigation and to follow the recommended irrigation amount if specified on the label. If an irrigation amount isn’t specified, Tamra Jackson-Ziems and I were talking about trying to apply with as small amount as possible (perhaps like 0.25″). She has chemigation data at 0.25″ vs. 0.50″ vs. ground application from 2005-2007, but not vs. aerial application. The data had a high degree of variability numerically in the yield data in spite of non-statistical differences. The only other info I could find was the University of Georgia recommends only 0.10″ on chemigation using fungicides, but they didn’t show any data. I encourage those who can to please consider doing this as an on-farm research study where chemigation occurs in pies throughout the field with other pies left untreated. I realize it’s not popular to leave areas untreated, but it may be of interest to you. For those asking about comparing aerial vs. chemigation for corn, that would be very difficult with one pivot with true research involving replication. Perhaps it could be done if a producer had a couple of quarters side by side, planted the same day with same hybrid and crop rotation where we could truly compare via research. If you do and that’s of interest to you, please contact either Tamra or myself. A couple have also discussed maybe applying half a pivot aerially and the other half via chemigation and just taking observations, which may also be beneficial to you.

We also released a few CropWatch articles this week on differentiating growth regulator herbicide injury in soybean and using a forensic method to diagnose off-target dicamba

Dicamba on Soybean: Because dicamba negatively affects leaflet margin cell division, direct dicamba exposure to nearly fully developed leaflets results in in a “draw-string” injury symptom at the leaflet tips, thus shortening the leaflet length. Keep in mind, however, that the translocation of dicamba from directly exposed leaflets to very young leaf primordia developing at new nodes at the main stem apex will also induce leaf cupping in those yet to emerge leaflets, even though these very young leaflet primordia were not directly exposed to dicamba. The same can be true for new trifoliolates occurring from additional stem branching at lower nodes. Photo via Purdue University.

injury in soybean. Please check them out at http://cropwatch.unl.edu. I hadn’t heard anyone really explain the difference between 2,4-D and dicamba in how they work in plants so felt that information was important in addition to the fact dicamba is highly translocateable and 2,4-D isn’t. That also has been important in home-owner discussions regarding off-target movement to garden produce. And, a reminder to all home-owners that weed control products used in lawns and empty lots often contain dicamba and/or 2,4-D…so it’s important to read those labels regarding environmental conditions in applying them and also when you can/can’t use grass clippings as mulch.

Buzzing Beetles: This past week, several people came to the office or called

2,4-D on Soybean: 2,4-D impacts cell division in the more central (major vascular) portion of the leaflet. Low-dose 2,4-D exposure induces injury that results in a “narrowed, strap-shaped” leaflet in which the leaflet veins are made more parallel. This 2,4-D-induced injury is often accompanied by a rugose leaf surface ― a botanical term describing a rough leaf surface of irregularly spaced bumps/wrinkles and prominent ridged/corrugated leaf veins. Low-dose 2,4-D exposure will also lessen leaflet area, but differently, by narrowing/elongating the leaflet. 2,4-D is also not highly translocatable, wheras dicamba is. Photo via Purdue University.

regarding large green beetles flying around that sounded like bumble bees. These are called Green June beetles. They only fly during the day. There are also smaller green beetles with white spots (tufts of hair) around the abdomen; those are Japanese beetles. Japanese beetles feed on crops in addition to favorites such as Linden trees and knockout roses. Both have larval forms that are white grubs and both have a one year life cycle. In the beetle form, both adult beetles are fond of ripe fruit such as grapes, berries, plums, and peaches. As larvae, the grubs feed on decaying organic matter and grass roots in the soil. However, the June beetle larvae can reach 2″ long creating larger tunnels in lawns and pastures as they move in the soil.

Some have said, “I thought June beetles were golden/tan!” And you would be correct! There’s several types of “June” beetles. The most common and perhaps most damaging is known as the June beetle or masked chafer which is golden/tan in color and has a one year life cycle. There’s also a May/June beetle (also known as the 3 year grub) which tends to do more damage in range/pasture ground. Those beetles are tan to brown/near black in color.

When it comes to damage, start looking for browning areas of turf occurring late July, throughout August, and early September. The turf may look like drought stress or fungal disease; however, if you can gently roll the turf back like a carpet, it’s most likely grubs (and you should also find the presence of grubs). Other signs of grubs can include birds, skunks, etc. tearing up your lawn. White grubs in general feed on decaying organic matter, lawn and ornamental roots in the soil. Grubs don’t tend to be an issue in fescue lawns or lawns that are low maintenance or newly established. They tend to prefer Kentucky bluegrass lawns that are highly maintained with fertilizer and irrigation. They also may be spotty in their feeding such as under yard lights or on irrigated slopes. The threshold level for turfgrass damage by masked chafer larvae is 8-10 white grubs per square foot of lawn…so I would assume that to be the case for all grub species. One or two grubs per square foot is normal and does not require control. If grub control is needed, products like Sevin or Dylox provide the best control for mature grubs and should be watered in after application.

- Green June Beetle (left) and Japanese beetle (right). Photo via Purdue Entomology.

- Masked chafer (June beetle). Photo via UNL Turf.

- May/June beetle. Photo via UNL Turf.

JenREES 6-24-18

Crop Update: What a blessing to have rain this past week! Grateful for how it provided much needed moisture into the top two feet in many cases. Updated soil moisture status will be at http://jenreesources.com. Some in our area and in other parts of the State received wind, hail damage, and flooding to crops. This week’s CropWatch at http://cropwatch.unl.edu shares information for those situations. A few summarizing points: for those with greensnap or with severe hail damage, you may wonder what potential yield may be based on your planting date and current plant stand. The following chart from Iowa State University and explanation of how to understand it may be helpful: https://crops.extension.iastate.edu/cropnews/2009/05/assessing-corn-stands-replanting.

Source: Iowa State University

For those with flooding, corn in the V7-10 leaf stage can survive for about 7-10 days in flooded water. Temperatures above 86F can result in greater stress on those plants than if the temps remain cooler than that during that time. Another consideration for the future, it’s not uncommon to find a disease called ‘crazy top’ of corn when the tassels begin to emerge. We’ve seen this the past several years where creeks or areas along waterways or field edges were ponded. There’s nothing you can do to prevent this.

For those with hail damage, damage from V7-10 leaf corn can result in a number of situations depending on the severity of hail. Minimal yield loss is assumed for leaf damage in crop insurance charts. Final plant stands will be important which will account for broken off plants that don’t recover. Stem bruising also isn’t factored in. For corn, bacterial diseases tend to be my larger concern at these growth stages. Bacterial top rot is one in which the plant dies from the top down and has a strong odor to it and creates a soft, slimy mess. Goss’ wilt is another concern-particularly systemic Goss’ wilt. You can check for this if you have a dying plant that doesn’t have a soft rot by taking a

Cross-section of stem showing systemic Goss’ wilt in the discolored vascular bundles.

cross section of the stem and looking for discoloration of the vascular bundles. You can also send plants like this to the Plant and Pest Diagnostic Lab in Lincoln for confirmation.

Regarding fungicide use on hail damaged corn, Iowa State and the University of Illinois did studies finding similar results. Both found no statistical difference in applying a fungicide vs. the untreated check in spite of small numerical differences. Regarding timing, the Iowa State study simulated hail damage at tassel and applied fungicide an average of 3 days and 8 days post-hail. There were no statistical differences on yield of the timing of the applications either. They did find statistically less fungal diseases in the hail-damaged plots vs. the non-hail damaged plots and speculated it was due to more air flow and less leaf area available for disease to occur. I have observed that fungicide can help with stalk strength and maintaining whatever green tissue remains when we had the 2013 hail storm in Clay County at brown-silk to blister corn. But this early, it’s hard to justify a fungicide application based on the data that’s available. If you’re interested in testing this for yourself, the following is an on-farm research Fungicide Protocol for Hailed Corn and Soybean.

For hail damage on soybean, many of the beans are at flowering or approaching flowering. Again, stem bruising isn’t counted in crop insurance assessments. I haven’t really observed bacterial or other disease issues necessarily from stem bruising in soybean. What tends to be more of an issue is those plants hardening off and becoming brittle to walk through. For soybeans, the blessing is that often new buds form and you will see increased branching which can help with canopy closure…it just can hurt right now when soybeans were already near canopy and we’re trying to reduce additional inputs for weed control. Things to consider are that pods may be closer to the ground from this increased branching and you may need to harvest earlier to help with getting beans that become brittle before snapping off in wind storms. I leave plant stands of near 60,000 plants/acre based on our soybean pop studies that received hail damage. If you want to prove any replanting differences to yourself, you may wish to consider the following Soybean Replant Protocol. We’d recommend waiting on herbicide apps till some new growth occurs, which is difficult when I’ve watched palmer essentially be not affected by hail and put on two new leaves within a few days in the past. Last year we started making herbicide apps 5-7 days post-hail. Additional hail resources are at a new resource called ‘Hail Know’ at: https://cropwatch.unl.edu/hailknow. There’s a lot of info I haven’t transferred to this site yet…but you can view photos and comments on hail recovery at numerous growth stages over time at my blog under the ‘Storm Damage’ category: https://jenreesources.com/category/storm-damage-2/.

Last week I shared the following video regarding determining timing of off-target dicamba movement to soybean: https://youtu.be/rQid7-vX-TU. Sharing again with an increase in the number of fields that were experiencing cupped symptoms last week.

JenREES 6-17-18

This past week contained many off-target herbicide concern calls. Prior to Memorial Day I had made a note that post-herbicide applications to corn began in much of the area and anticipated phone calls to begin in about two weeks. Most of the conversations this week were more FYI to let me know they had soybean leaf cupping.

Here’s a few things to consider if you are having soybean leaf cupping.

- First, was a post-herbicide application made to your soybeans? If so, check for any potential tank contamination (Check out this CropWatch article: https://go.unl.edu/fnig). If not, check out this publication (http://ipcm.wisc.edu/download/pubsPM/dicamba2004.pdf) to determine if any of the criteria mentioned could possibly be contributing to the problem.

- Determine how old the plant is by asking when the soybean was planted and even better when it emerged. A soybean plant will produce a new node every 3.75 days.

- To determine the timing of damage, I count the total number of nodes on the plant to the last trifoliolate where leaf edges are not touching. The total number of nodes may differ in different parts of the field such as irrigated and non-irrigated especially after herbicide damage and drought-stress (Example 8 nodes irrigated and 6 non-irrigated). Take the number of nodes X 3.75 to get total approximation of plant age. Then count back on the calendar to determine approximate emergence date. If I use 8 nodes in this example X 3.75 = around 30 days ago the plant emerged.

- I then count the number of nodes to the very first damage I see on leaves (Example 3). Multiply this number of nodes times 3.75 and count forward on the calendar from emergence to that date. For instance, in this case, damage occurred around 11 days after emergence.

- I also like to count how many completely unfurled trifoliolates are affected (Example 6 trifoliolates). Take that number and multiply by 3.75 (Example 6 X 3.75= approximately 23 days ago the damage occurred).

- In this example, it worked to count either direction (from emergence and from current date) to determine approximate timing of off-target movement occurring. In all the situations I’ve looked at thus far, the timing goes back to around Memorial Day with post-dicamba herbicide applications applied to corn.

- Auxin-like herbicides affect only cell division. Thus, fully developed leaves (no longer expanding via cell division) are not affected even though they may be expanding by leaf cell enlargement. Only the tips of the newest exposed soybean leaves may experience damage to dicamba as they are still undergoing cell division. Otherwise, it can take 7-14 days for leaf damage from dicamba injury to appear on susceptible plants and damage will occur typically 4-6 nodes. This is because dicamba is also translocated once inside leaf cells. Thus it impacts cell division of the leaf primordia at the stem apex. We may not even see those leaves yet because they are still enclosed in the stem apex tissue.

- In a matter of weeks, affected fields can go from appearing to have minor damage, to looking really bad, to growing out of damage. It looks worst when those affected nodes push upward giving the field a grayish/white cast to it as the leaves become much reduced in size and are tightly cupped. Eventually the leaves will begin to look more normal again in time (as long as a second off-target movement doesn’t occur).

What can you do? Water via irrigation and/or rainfall is the best recovery tool for dicamba damage. Waiting is another. We’re blessed to grow indeterminate soybean in Nebraska which continues to produce nodes and leaves upon flowering which allows our soybean to grow out of damage.

- Wait till harvest to determine any yield impacts if there are areas impacted vs. those which aren’t. Otherwise, field-scale damage is difficult to discern yield impacts.

- You can talk with your neighbors/ag retailers regarding what they sprayed. In our area of the State, it’s often difficult to pinpoint the source of off-target movement with so many applying dicamba products to corn for palmer control often around the same time-frame. Now that post-apps to soybean are also occurring, that may also become a challenge. Of all the fields I visited last year, less than a handful of farmers sought any sort of compensation and those were more often due to tank contamination issues. If you wish to pursue that route, you need to file a complaint with the Nebraska Department of Ag.

- For future dicamba applications, check out these best management tips: https://go.unl.edu/97ok.

- For those of you reading this in a source outside of my blog, I created a video to hopefully be more visual and clear on understanding this method of diagnosing timing. You can check it out at my YouTube site: https://www.youtube.com/user/jenreesources.

Bagworms: It’s June and one of my top questions has been “Have I found bagworms yet?” Well, they’re now feeding and forming new bags on junipers and spruces. What you’re looking for are not the old bags at this point, but very small (fingernail size) new bags that move as the caterpillar is feeding and making the larger bag. This video from Backyard Farmer (https://youtu.be/05A2quj9nO4) does a great job of showing various stages of bagworms and sharing on control methods. Check it out!

Irrigation Scheduling Workshops: Steve Melvin, Extension Educator in Hamilton/Merrick Counties asked I share about upcoming irrigation workshops hosted by UNL and Upper Big Blue NRD. The program will focus on installing the equipment and making irrigation scheduling decisions using the data generated by Watermark sensors. The workshops will be held from Noon-1:30 p.m. on June 25th at the Corner Café, 221 Main St in Stromsburg and also at the same time June 28th at the Hordville Community Building, 110 Main St. The Upper Big Blue NRD will provide the lunch. The first presentation will be Installation of Watermark Sensors and Data Logger presented by Dan Leininger, Water Conservationist with the Upper Big Blue NRD. The second will be Deciding When and How Much Water to Apply Using Watermark Sensor Readings presented by Steve Melvin. The irrigation scheduling strategies presented in Steve’s presentation can be used with any soil water monitoring equipment data. More information is available by calling Steve Melvin at (308) 946-3843 or visiting https://extension.unl.edu/statewide/merrick/.

JenREES 3/4/18

Grateful March is here! With the warm weather the past few days and geese flying, spring will be here before we know it.

Wheat Stem Maggot Webinar: With that in mind, several with cover crops have asked if we have an update on wheat stem maggot and the timing of termination. If you recall, last year we saw wheat stem maggot move from wheat and rye cover crops into newly emerged corn in some fields where the cover was terminated at or after planting. We’ve had several farmers in the area who have went to the later termination and it seemed to have worked well prior to last year. While I wonder if it was more of a fluke due to a warm February in 2017, Dr. Justin McMechan, Extension Crop Protection Specialist, collected maggots from infested fields and reared them to better understand their life cycle. I asked him to share a webinar on what he’s learned including recommendations and information on insects of cover crops in general. If you’re interested, please join us Wednesday, March 14th from Noon-1 p.m. at the following weblink: https://unl.zoom.us/j/976118766.

if we have an update on wheat stem maggot and the timing of termination. If you recall, last year we saw wheat stem maggot move from wheat and rye cover crops into newly emerged corn in some fields where the cover was terminated at or after planting. We’ve had several farmers in the area who have went to the later termination and it seemed to have worked well prior to last year. While I wonder if it was more of a fluke due to a warm February in 2017, Dr. Justin McMechan, Extension Crop Protection Specialist, collected maggots from infested fields and reared them to better understand their life cycle. I asked him to share a webinar on what he’s learned including recommendations and information on insects of cover crops in general. If you’re interested, please join us Wednesday, March 14th from Noon-1 p.m. at the following weblink: https://unl.zoom.us/j/976118766.

Dicamba and 2,4-D: Also received a number of calls last week regarding clarification on training required for dicamba and 2,4-D. There is no required additional training to apply 2,4-D products or any dicamba products other than the RUP dicamba products XtendiMax, Fexapan, and Engenia.

National Spray Drift Webinar: Join pesticide spray applicators from across the nation on March 15 for a webinar on “Strategies for Managing Pesticide Spray Drift” being presented by Nebraska Extension Weed Scientist and Application Technology Specialist Greg Kruger. The webinar is tailored to growers, pesticide applicators and other interested stakeholders who use pesticides and pesticide application equipment. It will be held from 10:30 to noon CT on that Thursday. Pesticide spray drift is the movement of pesticide dust or droplets through the air — at the time of application or soon after — to any site other than the area intended. Spray drift can affect people’s health, damage nearby crops, and pose a risk to non-target organisms. Kruger manages the Pesticide Application Technology Laboratory at the university’s West Central Research and Extension Center in North Platte, where he uses a wind tunnel to test pesticides and spray adjuvants for drift. Kruger has a BS from the Ohio State University, where he studied agribusiness and applied economics, and an MS in plant pathology and a PhD in weed science from Purdue University. This EPA program is geared toward reducing spray drift from pesticide applications to crops, fruits and vegetables, and aerial applications. It will cover general pesticide applications with a focus on agricultural applications. The EPA program is free, but participants are asked to register in advance here: https://register.gotowebinar.com/register/1526938365731023875.

Kiwanis Club of Seward and SCCDP Ag Banquet: The 50th Annual Kiwanis and SCCDP Agricultural Recognition Banquet will be held Monday, March 19, 2018 at the Seward County Ag Pavilion at the fairgrounds in Seward, NE. The banquet is held during this time in honor of National Ag Week, March 18-24, 2018. The event kicks off with a social hour of wine and cheese beginning at 5:30 p.m. followed by a Prime Rib Dinner beginning at 6:30 and Awards Presentation beginning at 7:00. Mike Meyer, radio announcer, will serve as the evening emcee with Governor Pete Ricketts as the featured speaker. Cast Family Farms (Roy, Doug, David, Patrick, Nathan, and Dustin) will be honored as the 2018 Seward Kiwanis Outstanding Farm Family of the Year. Bill White with The Austin Company, will be honored as the Seward County AgriBusiness of the Year. Tickets cost $25.00 and can be obtained by contacting Shelly Hansen at the Cattle Bank at 402-643-3636.

Farmer Appreciation Open House will be held for the public at the York County USDA Service Center in York March 5-8 from 8:00 a.m.-4:00 p.m. The Farm Service Agency, Natural Resources Conservation Service, Upper Big Blue NRD, and Nebraska Extension will have informational booths. Light refreshments and door prizes will also be available.

Pruning Trees: Kelly Feehan, Extension Educator in Platte County shares, “With shade tree pruning commonly started in March, there is a general rule for when to start pruning young trees. After planting a tree, avoid pruning for a few years; especially avoid removing the lowest limbs. Leave lower limbs until they are about one inch in diameter. It is fine to remove double leaders and dead or damaged branches at planting, but otherwise avoid pruning newly planted trees for about three years. From four to ten years after planting is the most important time for pruning young trees to develop a strong branching structure and to remove branches when small. Ideally, prune branches before they reach two to four inches in diameter. Smaller wounds seal and callus over quicker than large wounds and more efficiently produce chemical walls that prevent the spread of decay within a tree. It is important to avoid pruning too much at any one time so remove a few branches each year.”

JenREES 2/18/18

Dicamba Best Management Practices: Last week I finished pesticide and dicamba trainings for our area. In each of the meetings, off-target injury from dicamba in 2017 was discussed. A few weeks ago in my column, I shared how dicamba applications to corn played a role in our area of the State. I’ve also received questions regarding best management practices for all dicamba applications in 2018. A team of Nebraska Extension Specialists and Educators have been discussing this for several months based on the research we could find in the literature. Grateful for this team working together and you will see three articles in this week’s UNL CropWatch at http://cropwatch.unl.edu. These articles include: best management practices for all dicamba applications in 2018, potential off-target movement from corn applications, and the tricky task of removing dicamba residues from sprayers. Please check them out! This week’s CropWatch also features several student intern reports on soil, forage, and cover crop research.

Farm Bill Meetings: A new federal farm bill is due this year and is under development in Congress. With action completed on a federal budget including some agricultural programs, the farm bill process could pick up quickly with proposals and legislation fully debated in the coming weeks.

Reminder of the last Farmer/Rancher College program Feb. 23 in Geneva (10 a.m.-3 p.m.) at the Fairgrounds on the farm bill and crop insurance. Great lineup of speakers including Steve Johnson from Iowa State University and Brad Lubben with UNL. No charge but please RSVP (402) 759-3712 as they are still taking registrations.

There’s also a series of Farm Bill Meetings upcoming in Nebraska and Kansas in late February/early March. The meetings will provide an overview of the current debate and current economic conditions in agriculture which help frame the discussion and will look at crop and dairy commodity programs, conservation programs, and nutrition programs and other policy issues, as well as proposed crop insurance changes.

Leading the discussion will be Mykel Taylor and Art Barnaby from Kansas State University and Brad Lubben from the University of Nebraska-Lincoln. Taylor is a farm management specialist with expertise in producer decision-making, including in-depth analysis of the 2014 farm program enrollment decision. Her analysis of past decisions and outlook will provide perspective on the commodity programs, the potential changes and the decisions ahead in 2019. Barnaby is a national expert in crop insurance with keen insight on the features and performance of crop insurance. His work will explore the proposed changes and the potential ramifications to the program and to producer crop insurance and risk management decisions. Lubben is a noted expert in agricultural policy with insight on both the farm bill issues and the process. He will help frame the debate and the expectations for new programs and policies to provide perspective on the broader budget and policy challenges facing members of Congress in writing the new farm bill.

Each meeting will run from 9:00 a.m. to 2:30 p.m. Registration will begin at 8:30 a.m. with refreshments and lunch served. The registration fee is $20 if pre-registered five days before the date of each meeting, and will increase to $30 after the deadline or at the door. The fee covers the meal, refreshments and meeting materials. To register, visit http://www.agmanager.info/events/2018-farm-bill-meetings and click on the meeting you wish to attend. Locations include:

• DODGE CITY, KS.: Feb. 28, Knights of Columbus Hall, 800 W. Frontview, Dodge City, KS. Host: Andrea Burns, aburns@ksu.edu or 620.227.4542

• MANHATTAN, KS.: March 1, Pottorf Hall – CiCo Park, 1710 Avery Ave., Manhattan, KS. Host: Rich Llewelyn, rvl@ksu.edu or 785.532.1504

• MEAD, NEB.: March 5, ENREC near Mead, Eastern Nebraska Research and Extension Center, 1071 County Road G, Ithaca, NE. Host: Keith Glewen, kglewen1@unl.edu or 402-624-8030

• HASTINGS, NEB.: March 7, Adams County Fairgrounds, 946 S. Baltimore, Hastings, NE. Host: Ron Seymour, rseymour1@unl.edu or 402-461-7209

Further information is available at http://agmanager.info or http://farmbill.unl.edu or by contacting the meeting host at each location.

Central Nebraska Cover Crops Conference: From grazing cover crops, seeding methods, innovative methods to incorporating cover, and more, the Central Nebraska Cover Crops Conference offers the latest information to help Nebraska growers profitably incorporate cover crops into their operation. The event will be held Friday, March 2 at the Merrick County Fairgounds with donuts provided by Lincoln Creek Seed at 9:00 a.m. The event has a great lineup of speakers including Paul Jasa, Extension Engineer; Keith Berns, Green Cover Seed and Nebraska Farmer; Dean Krull, Extension Demonstration Project Coordinator; Mary Drewnoski, Extension Beef Specialist; Daren Redfearn, Extension Forage Specialist; and Steve Melvin, Extension Educator.

Exhibitor space is still available for anyone wanting a booth. The event is free but please RSVP to (308) 946-3843. More information is available at https://extension.unl.edu/statewide/merrick/.

SE Nebraska Soil Health Conference will be held March 5 at the Kimmel Expo Center in Syracuse, NE. The program begins at 9 a.m. (Registration 8:30 a.m.) with topics including no-till/cover crop research update, best management practices for planting into cover crops, grazing cover crops, and two Iowa farmers sharing on how they utilize cover crops in corn and soybeans and on their farms. This event is free and lunch is included but pre-registration is necessary by calling (402) 274-4755 or at http://go.unl.edu/senebsoilhealth.

A Sprayer Applicator Clinic will be held on Tuesday, March 6, 2018, from 11:30 a.m. to 4:00 p.m. at the Kimmel Ag Expo Building in Syracuse, NE. “By attending this clinic, you will be a better prepared spray applicator,” says Greg Kruger, Weed Science and Pesticide Application Technology Specialist from North Platte, NE. Register by Friday, March 2, 2018, by contacting Nebraska Extension in Nemaha County at 402-274-4755. The cost of the program is $20 per person. Checks should be made payable to University of Nebraska-Lincoln and mailed to the Nemaha County Extension Office, 1824 N St, Ste. 102, Auburn NE 68305. Lunch is being provided by these sponsors: Midwest Farmers Cooperative, Dean Seeds – Syracuse NE, Andy Wellensiek – Channel Seed, Cook, NE, and University of Nebraska-Lincoln Extension. For more details regarding the clinic see the https://extension.unl.edu/statewide/nemaha/unl-sprayer-applicator-clinic/.