Monthly Archives: January 2026

Pesticide App Regulations Part 2

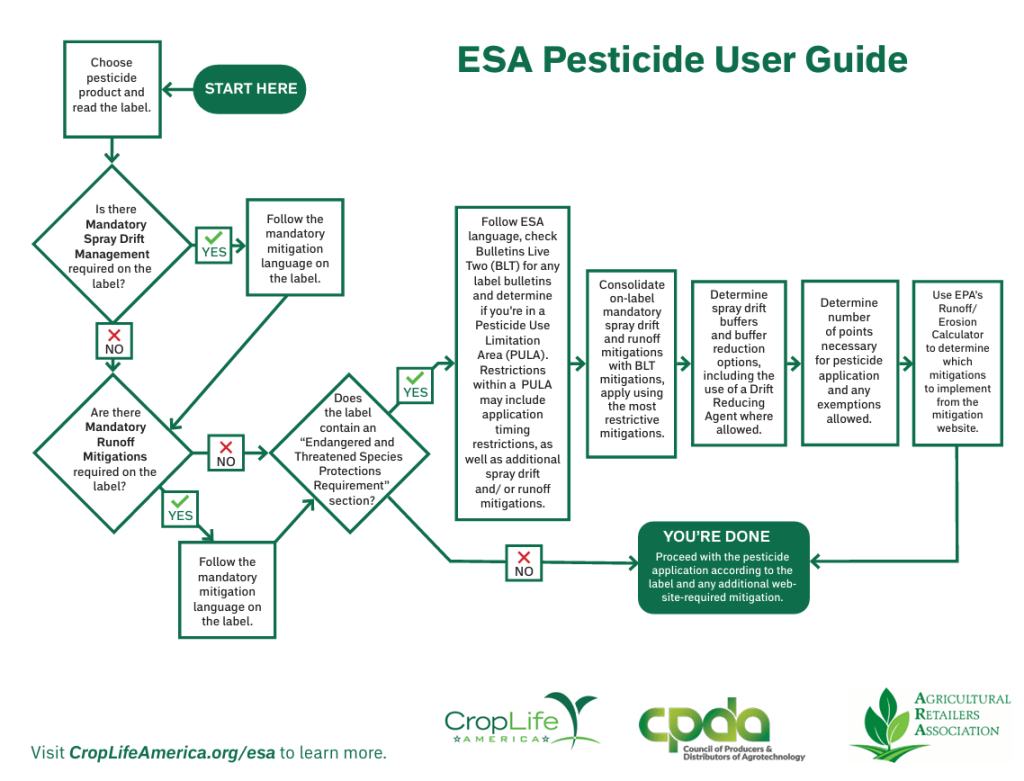

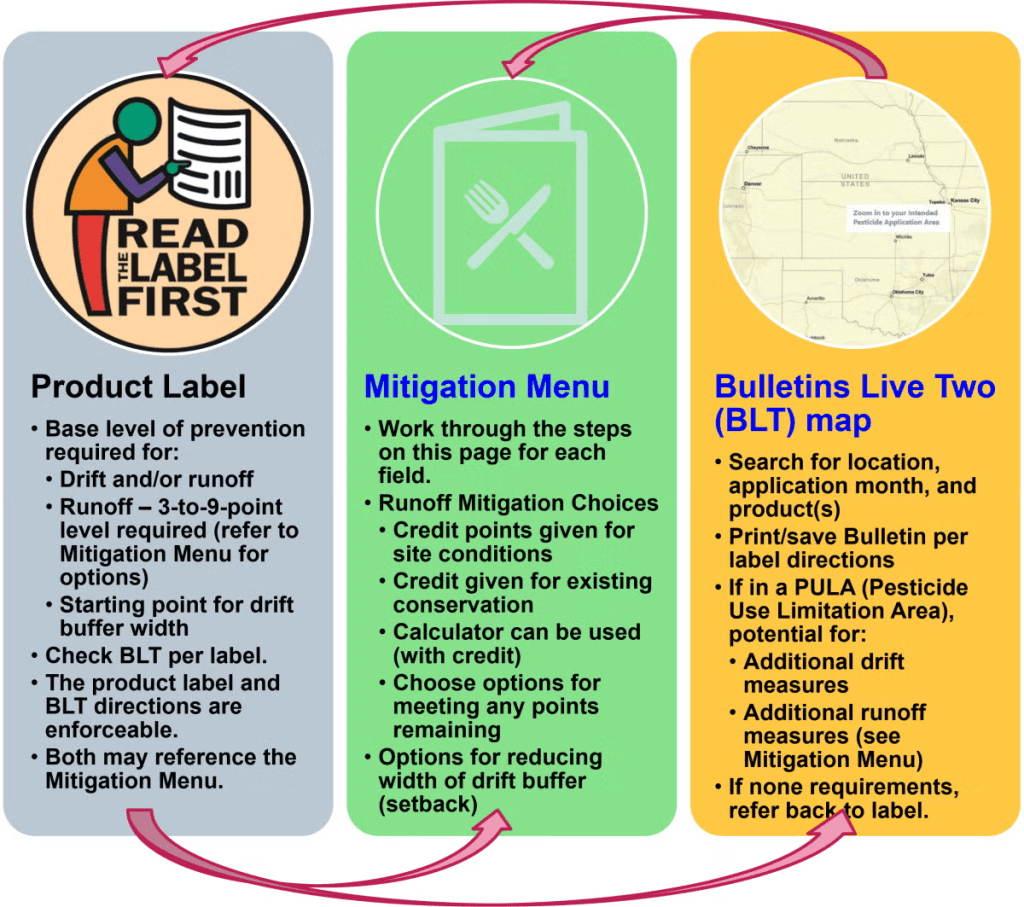

Last week I shared the background information on the Endangered Species Act (ESA) language. There’s easier to understand graphics I’ve included at jenreesources.com. The following are what growers need to do to comply with rules for 2026.

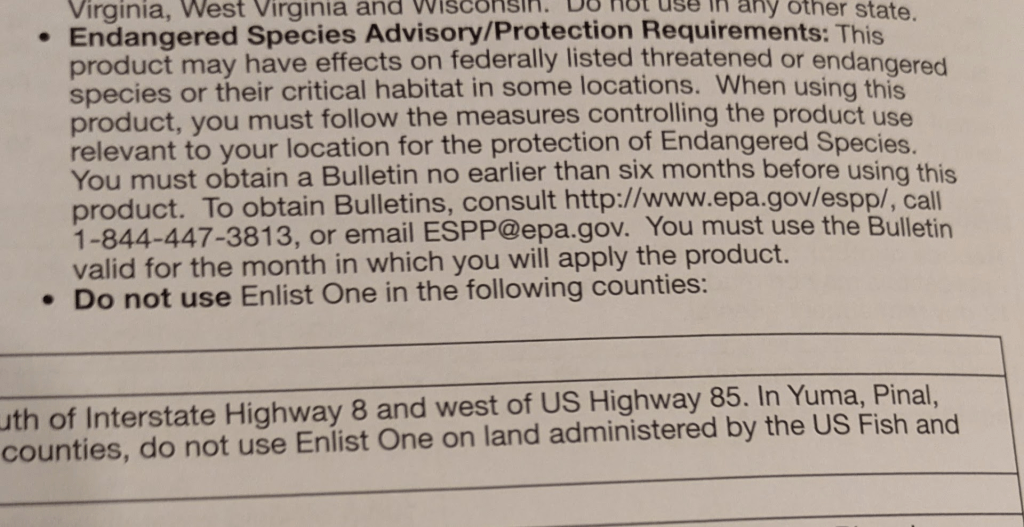

I know there’s a lot of concern about these new rules. IF compliance with ESA is needed for a specific product, the product label will state Endangered Species in bold letters (pictured below). The only way to know is to read the product label. Enlist One, Enlist Duo, and Liberty Ultra all have ESA language on them. Ultimately, if the product label says you need to comply with the Endangered Species Act, then you must go to Bulletins Live Two and print off bulletins for any field that product will be applied on in 2026. If it doesn’t specify ESA, then you don’t need to do this step.

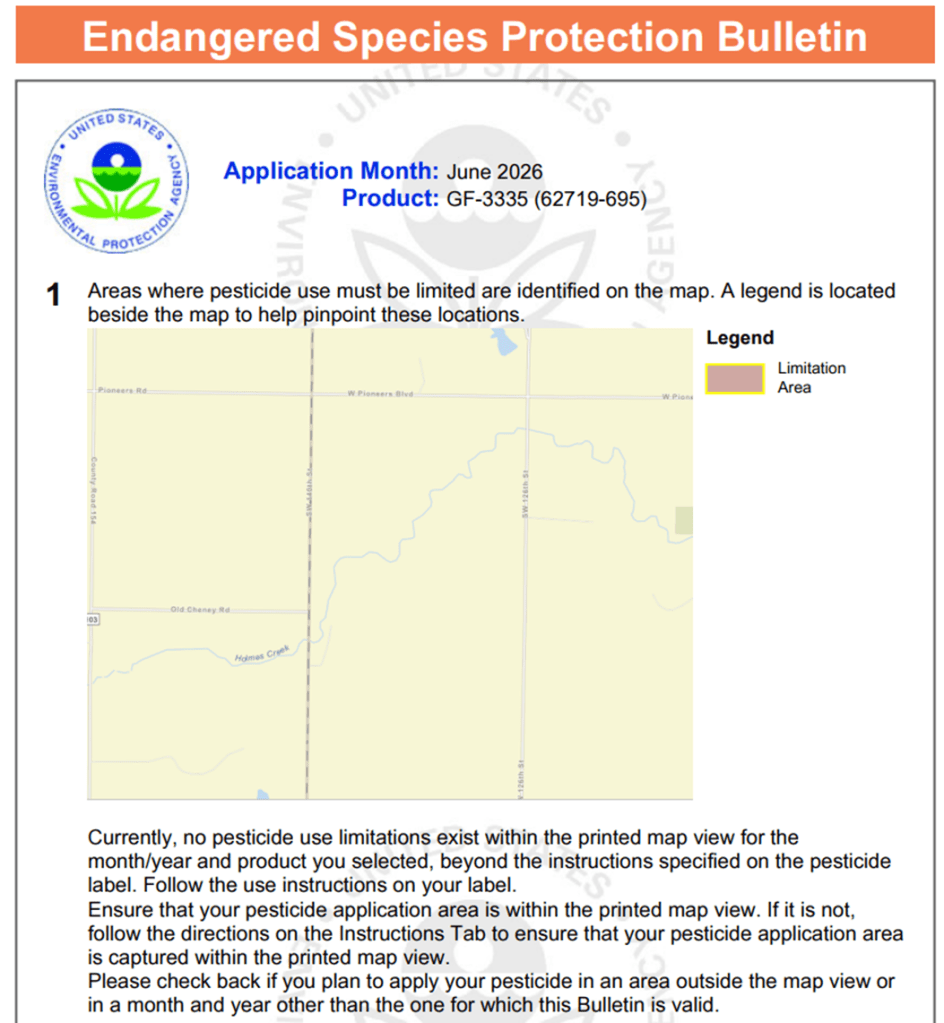

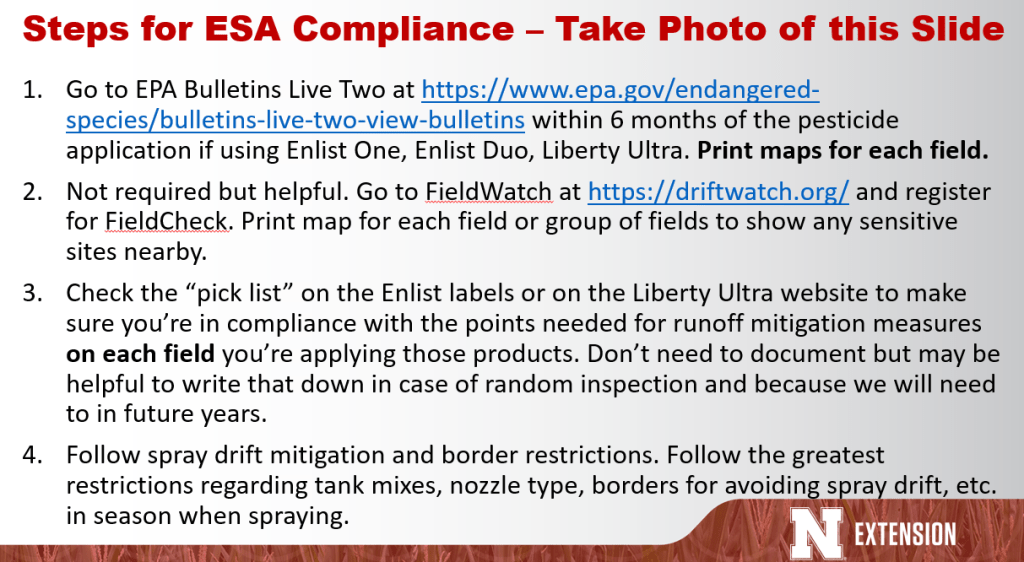

1-Go to EPA Bulletins Live Two at https://www.epa.gov/endangered-species/bulletins-live-two-view-bulletins within 6 months of the pesticide application if using Enlist One, Enlist Duo, Liberty Ultra or any product that specifies ESA language. When you get to the website, use the map or search feature to zoom in to your fields. Add the EPA registration number for the product you will be applying. It will then select the product. Select the month when the product will be applied. It will then show you a map of any Pesticide Use Limitation Area (PULA). If any exist, you must follow the specified restrictions. The map can then be downloaded and printed. Keep the map with your pesticide records. You need to print maps for each field you are using these products on. If you are applying these products in different months on the same field (ex. May and June), the bulletin needs to be printed for each of those months and kept with your records.

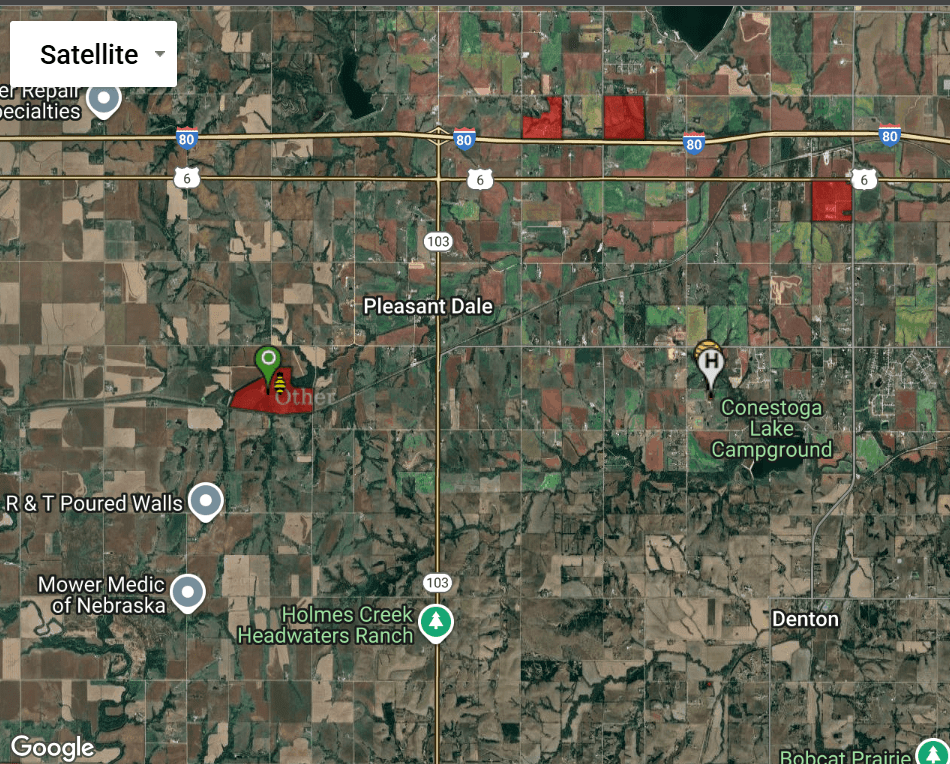

2-This step is not required. However, I’m unsure how we all comply with the sensitive site restrictions and buffers if we don’t do this step. Go to FieldWatch at https://driftwatch.org/ and register for FieldCheck if you’re not already registered. This is the old DriftWatch site where we as pesticide applicators can view any sensitive sites around our fields to avoid off-target movement to sensitive crops. You can select this field by field or if you have several fields in an area, you can draw an area on the map that encompasses all the fields. That’s what I did and then I’m going to label the fields on the map I printed. It provides a time stamp of when you check this site, so I’m just printing it and keeping it with our pesticide records.

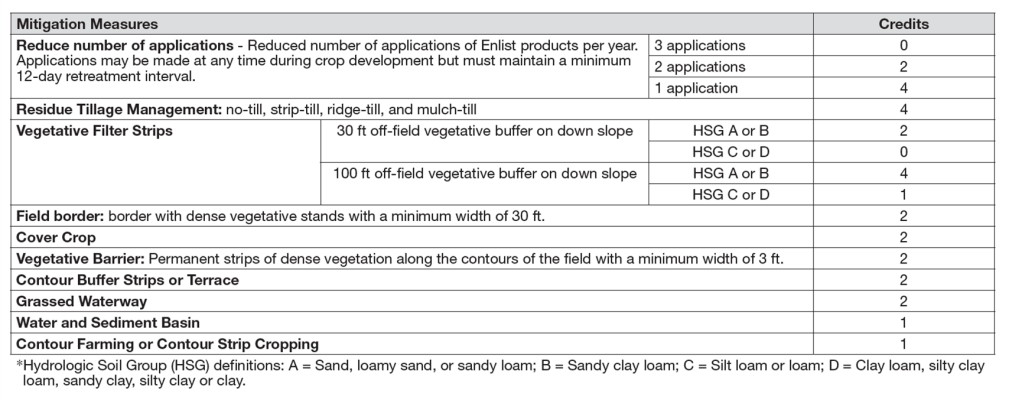

3-Check the “pick list” on the Enlist labels or on the Liberty Ultra website to make sure you’re in compliance with the points needed for runoff mitigation measures on each field you’re applying those products. You don’t need to document this for 2026, but I’d encourage us to write these down in our records as we will need to document this in future years. The number of points required and the mitigation measures from which to choose will vary depending on the specific label, so you must read the labels.

4-Spray drift mitigation and border restrictions also need to be followed. Follow the greatest restrictions regarding tank mixes, nozzle type, borders for avoiding spray drift, etc. in season when spraying.

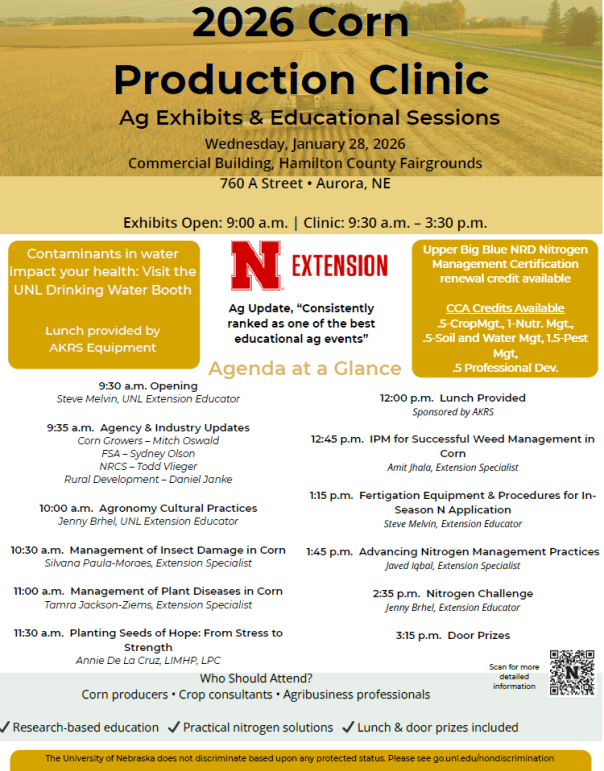

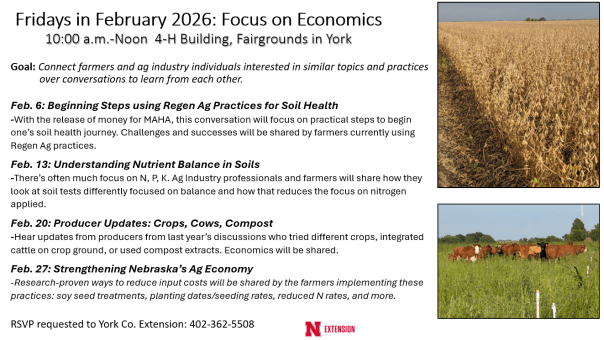

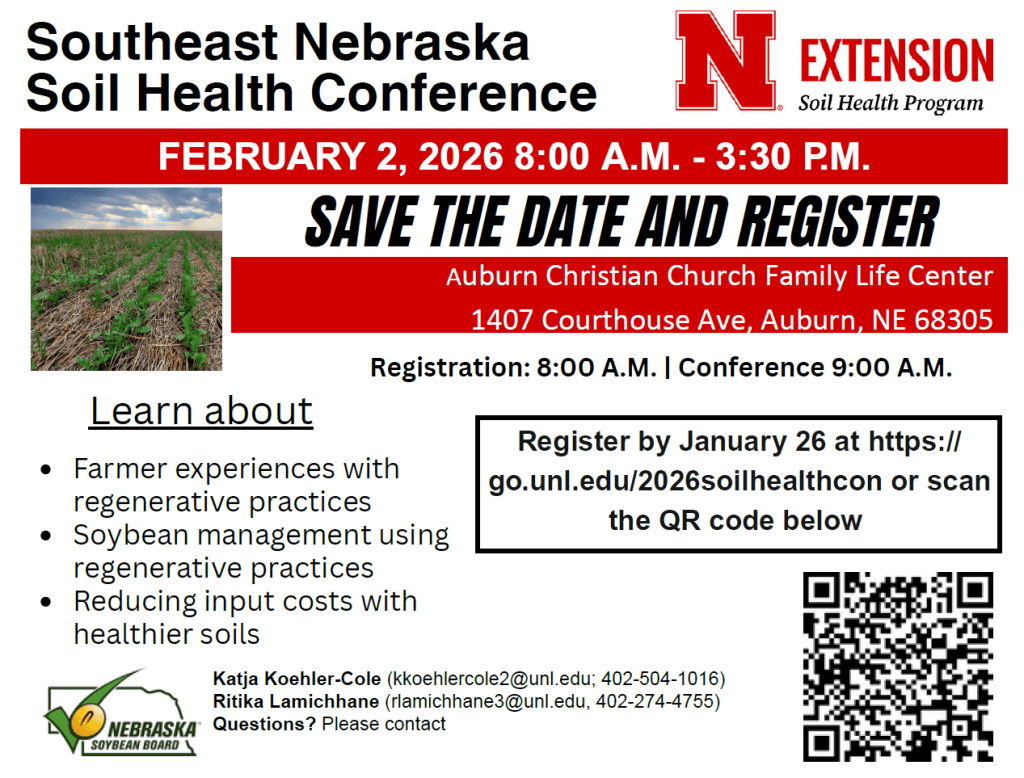

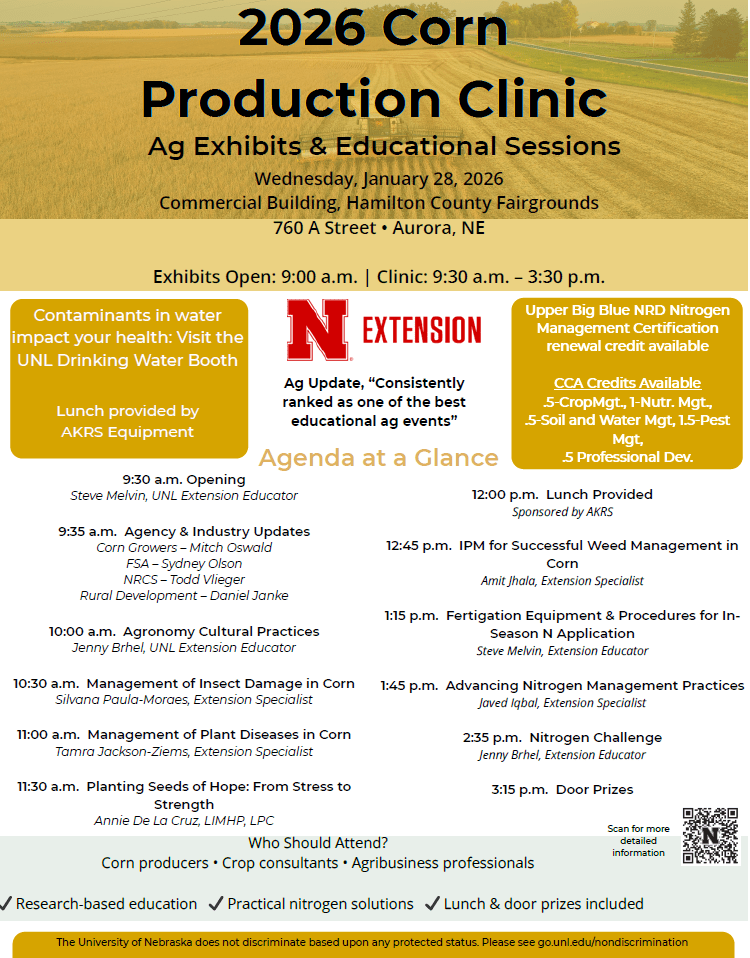

Upcoming Meetings: A quick note of upcoming meetings including the Nebraska Corn Clinic in Aurora on Jan. 28, Eastern NE Soil Health Conference in Auburn on Feb. 2, and my first Friday in February conversation on “Beginning your soil health journey” on Feb. 6th in York. Flyers are below or can be found at https://jenreesources.com/upcoming-events/.

Pesticide App Regulations Part 1

Last week was the kickstart to meeting season for me and it was great to see those of you at pesticide trainings and the Nitrogen Challenge meeting. For this column, I wanted to share a little more detail about the changes for this coming growing season regarding pesticide label language and requirements for the endangered species act (ESA) to mitigate drift and runoff. The information below came directly from a CropWatch article (https://go.unl.edu/skj7) written by Dr. Milos Zaric with UNL Agronomy, Greg Puckett with the UNL Pesticide Office, and Craig Romary with the Nebraska Dept. of Ag. Next week I will simplify this into specific steps to help you be in compliance for the 2026 growing season.

“Both Enlist One® and Liberty® ULTRA include ESA compliance requirements on their labels. These are not optional; they are enforceable use directions intended to protect federally listed species and their habitats (as well as other non-target plants and animals) from potential exposure due to off-target pesticide movement.

Before applying any listed product with ESA compliance requirements, applicators must consult the EPA BLT (Bulletins Live Two) map web tool to determine whether any application restrictions apply to the time and location of their planned application. A valid bulletin must be obtained within six months of the application, and the version specific to the planned month of application must be followed.

When applying multiple pesticide products as a tank mix, applicators must follow the most restrictive label requirements, including any ecological spray drift, runoff and erosion mitigation measures associated with either product. This added responsibility means users must verify compliance before making applications, particularly when operating in areas designated as vulnerable under the EPA’s mitigation framework.

The runoff and erosion mitigation measures will have a point system: each mitigation measure carries a point value, and to comply, the points for each site must meet the points for the product. Ecological spray drift mitigation will have a starting distance for a buffer or setback. Each mitigation measure allowed by the label will reduce that starting distance by a specific percentage. Depending on the level of mitigation implemented, buffer distances may be reduced — and in some cases to 0 feet — if the cumulative mitigation credits meet or exceed the required threshold.

Understanding and implementing these practices helps maintain compliance, reduce off-target movement, protect threatened and endangered species, their habitats, and other non-target plants and animals, and ensures continued access to essential row-crop protection products. This list is not exhaustive, and as new products are introduced or re-evaluated during registration renewal, they may include updated ESA-specific language and additional mitigation requirements.”

2026 Pesticide Training

Pesticide Training: This is the big year for pesticide training where the majority of people in the State need private applicator certification. There are a number of trainings available if you’re unable to attend the dates/times in the county you reside in. All trainings are listed at: https://go.unl.edu/psep26.

I apologize for the confusion and need to correct something I wrote regarding pesticide training. What I shared was the way we had always been taught was the law, but I was told by Nebraska Dept of Ag this week that the way it’s been written doesn’t share the whole information. When it says certified applicators are ones who “purchase and use restricted use pesticides”, the “purchase” is referring to “purchase by a retailer”. Thus, for those of you who are solely relying on a Coop or ag retailer to apply your restricted use pesticides and you are not applying them yourselves, you technically do not need a private applicator license. Feel free to call if you have specific questions regarding your situation.

The first trainings in York are this Thursday, January 15th at 9 a.m. and 1 p.m. at the Cornerstone Event Center (Fairgrounds) in York. We have been asking for RSVP to 402-362-5508 to save on the time for registration at the door, but walk-ins are welcome. Attendees need to bring a valid driver’s license or legal identification and $60/person. Those who are recertifying should also bring your NDA barcode letter, but we have other paperwork if you don’t have that for some reason.

If you don’t prefer to do the face to face training, other ways one can certify as a private applicator include an online self-study course and exam (cost $100) or attend the all-day Crop Production Clinic (cost $110) RSVP: https://agronomy.unl.edu/cpc/.

Crop Production Clinics: Especially for commercial and non-commercial applicators, Crop Production Clinics is the easiest way to recertify for the 00 and 01 categories. Please register at: https://agronomy.unl.edu/cpc/ for the location you wish to attend.

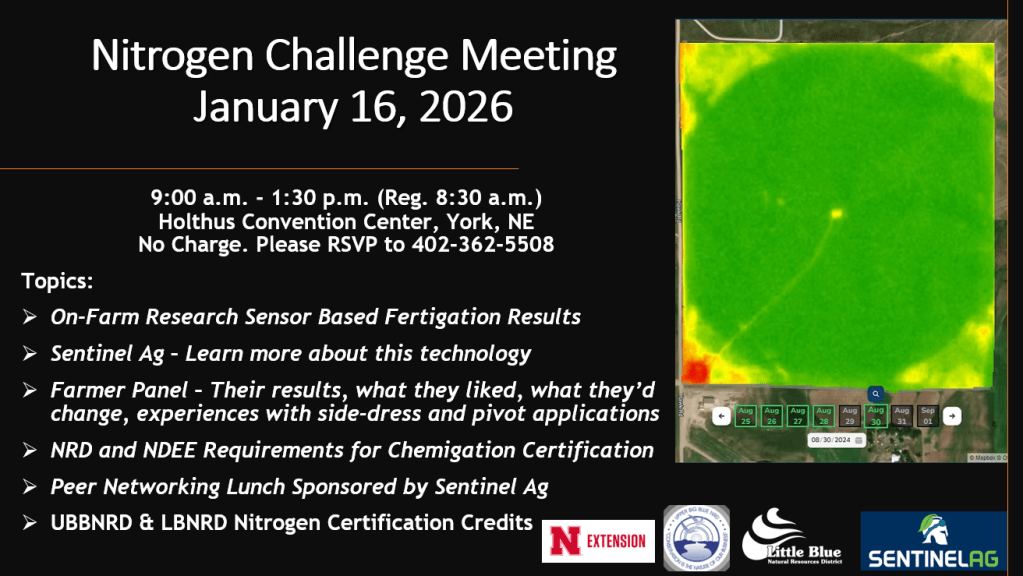

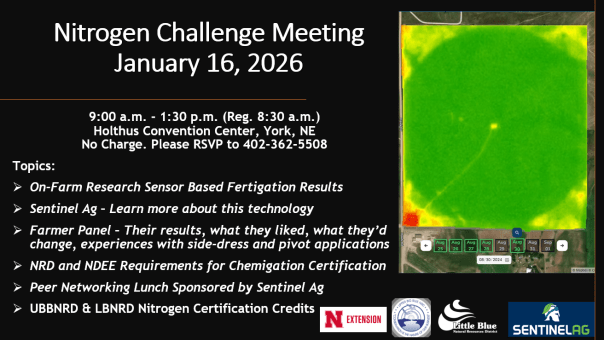

Also a reminder of the Nitrogen Challenge this week on Friday, Jan. 16th beginning at 9 a.m. at the Holthus Convention Center. If you’re interested in learning more about better managing nitrogen resources on your farm and most likely saving on nitrogen inputs, I hope you will consider joining us. Please RSVP to 402-362-5508 for meal count.

Reducing Nitrogen Inputs

With higher input costs and low commodity prices, I’ve been thinking how to be of help to the farm community I serve during these times. A small group of farmers and I met before Christmas. We talked about the difficulties the farm economy is facing yet also talked about realistic things that can be done to save money right now. One of those is around nitrogen and thus, we planned a Nitrogen Challenge Meeting on Jan. 16th at the Holthus Convention Center in York beginning at 9 a.m. The goals of this meeting are to share the research-based results from using in-season nitrogen management via Sentinel Ag, understand how to use this technology, and share testimonies from growers utilizing this technology. They wanted to create a peer network of famers supporting farmers during the growing season with this technology-so the first step will be a peer networking lunch sponsored by Sentinel Ag. The NRD is providing nitrogen certification credits. There is no charge but please RSVP for the meal count to 402-362-5508 or jrees2@unl.edu.

Why have I stressed nitrogen so much? In the Upper Big Blue NRD newsletter, Terry Julesguard wrote an article about nitrogen in the NRD based on the information provided by the Phase 2 and 3 reports. You can read the full article at: https://www.upperbigblue.org/increased-nitrogen-efficiency-brings-new-questions. In this excerpt Terry shares, “The numbers that stand out are the residual nitrate nitrogen in the soil:

- Corn-on-corn field increases from 33 lbs/A average to 86 lbs/A, an increase of 202%.

- Corn/bean rotation field increases from 32 lbs/A average to 86 lbs/A, a 212% increase.”

I know most farmers are seeking to do their best. The data is showing we’ve increased soil nitrate post-season by over 200%, meaning we’re overapplying N. We talk about the nitrate legacy from past generations, but this is the legacy we’re leaving right now in the soil for our kids and grandkids.

Soil tests in this area of the state from the 2025 season are showing residual soil nitrate is available to reduce the amount of nitrogen applied next growing season. This provides an opportunity to save on nitrogen input costs. No agronomist, including myself, can tell you exactly how much nitrogen you will need because we don’t know the weather/soil conditions for each piece of ground each year. This is why sensing what the plant needs is so powerful using technology like Sentinel Ag.

We have an opportunity to change the nitrogen story now-with us! On-Farm research with Sentinel Ag (2022-2024) in our part of the State showed an average 56 lb N/ac savings without impacting yields, while leaving an average of 5 ppm Nitrate in the top two feet. No other product or practice has proven that in our area of the State via on-farm research. It’s about using technology to manage the nitrogen the plant needs to the best of our ability. Thus, the Nitrogen Challenge in which I’ve asked growers to consider only applying a base rate pre-plant of 50-100 lb N/ac and apply the rest of the nitrogen in-season using a sensor-based technology like Sentinel Ag. Sentinel Ag uses satellite imagery to sense when a corn plant is becoming nitrogen stressed before our eyes can see it. The research was originally developed at UNL and the grad student (Jackson Stansell) then developed a company (Sentinel Ag) around it. Please consider learning more by joining us for the Nitrogen Challenge meeting on Jan. 16th. Farmer testimonials at: https://go.unl.edu/f3si.