Category Archives: on-farm research

Crop Updates 6/16/25

Wheat stem maggot in corn and herbicide injury issues have been my top questions the past few weeks. A team of us wrote a more detailed article of what we’re seeing and recommending regarding wheat stem maggot in CropWatch: https://go.unl.edu/atx9. Regarding herbicide injury, it perhaps is amazing this doesn’t happen more with all the traits we have. As spraying season continues, please double check fields for which traits are present to ensure the wrong herbicide isn’t applied to create potential crop injury. The one that has happened the most this season is glufosinate (Liberty) applied to non-Liberty link corn. The growth stage timing and rates of those applications make a huge difference on what we’ll see on corn survival.

Also, please always be checking growth stage of plants inside the field prior to herbicide applications. Crops have shorter internodes early on making them somewhat shorter than what we might expect. With June 21 coming this weekend as the longest day of the year, I’m anticipating we’re also going to see some blooms by this weekend/early next week with as many soybeans went in early this year.

As side-dress applications of nitrogen have been made in fields, it made me think of more on-farm research studies we’re conducting this year that might be of interest. They all involve using plant-based sensing from Sentinel Nutrient Management (also known as Sentinel Fertigation). Since not everyone who has irrigation systems wants to apply nitrogen through their system and because we have plenty of non-irrigated acres in the state, On-Farm Research is working with Sentinel to sense what the crop needed for side-dress applications this past year. There’s also opportunity for those with hi-boy machines to use this technology to apply nitrogen later in the season.

You’ve heard me share the on-farm research results about nitrogen savings using this sensing technology. In our area of the state, growers have used this technology in corn, soybean, and seed corn. This year, I know of growers also trying it in wheat and sorghum.

For on-farm research, I’m super excited to learn more from three studies that have had a history of cover crops and grazing! Each year, growers ask when to expect the nitrogen and other nutrients to be released from cover crops. Journal articles fairly consistently mention a 6-week time-frame. It ultimately depends on the Carbon:Nitrogen (C:N) ratio of the covers and rainfall to activate the biology. I’m excited to see if we can capture this time-frame better through satellite imagery using Sentinel Nutrient Management. The goal would be to see if we could better time nitrogen applications in addition to rates better using sensing technology.

Another question growers have asked is “how do we know how much nitrogen to credit after grazing cover crops?”. We hope to better answer this on two fields this year using sensing technology. Two of the on-farm research studies are following “Regen Years” where the land was planted to multi-species cover crop mixes and grazed all year instead of taking crops for grain. One is irrigated while the other is non-irrigated and both have nitrogen rate ramps associated with them. We plan to have a field day on the irrigated site in late July and will share more details later. Looking forward to what we will learn and sharing the results!

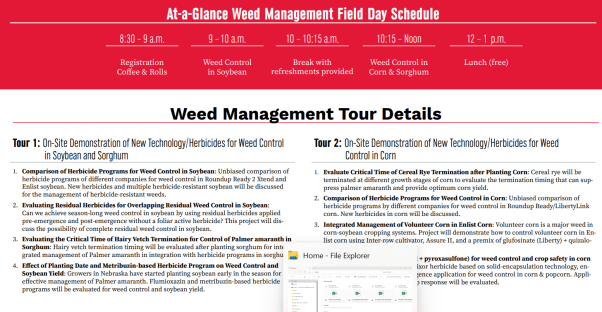

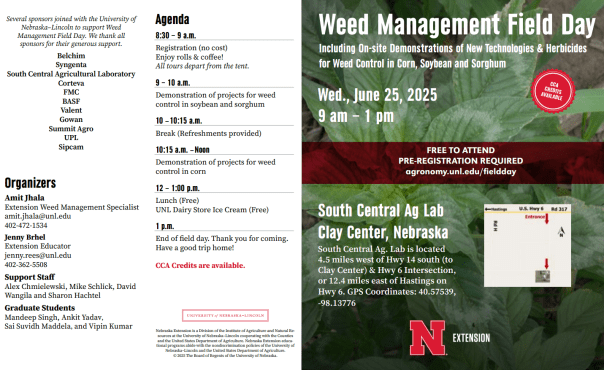

Reminder: June 25 Weed Management Field Day at UNL’s South Central Ag Lab near Clay Center, NE. Details at: https://go.unl.edu/qemk.

Compost Extracts Part 2

With Memorial Day this weekend, grateful for all those who gave the ultimate sacrifice for our freedom and to the families left behind.

Last week, I shared some information on compost extracts. Curt Arens, editor of Nebraska Farmer magazine, responded sharing an article he wrote of a group in northeast NE working with compost extracts: https://www.farmprogress.com/soil-health/1113f1-1400-slideshow.

The “why” behind using compost extracts is to build a diversity of locally grown biology. The goal is to reduce synthetic nitrogen and other nutrients on their farms by allowing the biology to process the currently unavailable nutrients in the soils. The hope is to also increase microbial activity to naturally ward off insect and pathogen pests to reduce chemicals in the system.

The extraction process of removing the microbes from the compost has been done a number of ways. One farmer used 5 gallon buckets of compost, paint screens, water in a stock tank and an air hose to agitate. I’ve seen other farmers agitate and screen 5 gallon buckets of compost various ways into cleaned out plastic totes or cone bottom tanks. Extraction equipment can also be purchased. It does take time and is often made the morning or night before of planting and/or foliar application.

A tool I use more often is my microscope. Until a few years ago, I never thought to look at soil under my microscope; it takes practice and time. It’s opened my eyes to a whole new world of understanding and questions. With the compost extracts, I’ve seen great diversity: bacteria are common, but also fungal spores, amoebas (protists), and nematodes. I’ve learned by dunking seeds and looking at how chemical seed treatments interact and don’t interact with biology. I’ve looked at various products from a jug. I’ve dunked roots of young seedlings. It’s incredible how some biological products provide much life to the roots with microbial diversity while also viewing how chemical seed treatments did their job and the minimal associations with microbes formed. It’s a tool that I think more farmers would find helpful if time was scheduled to observe and learn.

The on-farm research studies with compost extracts were complicated studies including various nitrogen rates. So, I will share highlights and you can view the full reports beginning on page 162 of the 2024 on-farm research book.

Seward Study 1 (pg 171): In this 3-year study, the grower had two years of corn and one year of soybeans with a Check treatment, compost extract treatments, Pivot Bio (in the corn years) on the same strips. In 2022, there were no yield differences between the Check and the two compost extract + 106 lb N/ac nitrogen rates. In 2023, there were no yield differences for any of the treatments in spite higher and lower N rates. In 2024, there was no yield difference between the Check and Johnson Su compost extract areas. Encouraging is no lower yield with the reduced N and compost extracts.

York Study 2 (pg 167): In this 2-year study, there were no yield differences between any treatments in 2023 in spite of a 20% reduced N rate. The grower questioned if he was going low enough with N, and in 2024, did a nitrogen ramp study with compost extract. There were no differences between the 190 lb N/ac full N rate, 120 lb N/ac reduced N rate, and 120 lb N/ac + compost extract. Analyzing just the 120 lb N/ac rate vs. 120 lb N/ac + compost extract resulted in the a significant yield advantage to the compost extract, which was encouraging to the grower.

Lancaster Study 3 (163): In this non-irrigated study, nitrogen was the primary limiting factor amongst the treatments. The conclusion was biology needs moisture in the midst of drought.

Grateful for all who gave the ultimate sacrifice for our freedom!

Compost Extracts Part 1

During the winter months, farmers often called asking if we had research on X biological product. I heard a few of them deem 2025 as “the year of the biologicals” with how often different products would show up in ads and be discussed in meetings. It seems like the majority of companies are adding some type of biological or biostimulant to their product line. Why? I think mostly because there may come a day when we have to rely less on chemicals for ag production. We also have an increasing number of growers who are trying to reduce the amount of chemicals and synthetic fertilizer they use. Maybe there’s something to “it feels right or good” as well.

While we don’t have research on the majority of the products on the market, we are gaining more on-farm research results in homemade biologicals called “compost extracts”. If you search for this term, you will find the terms “compost extracts” and “compost teas” which are often mentioned for gardening settings. In recent years, some farmers seeking a regenerative ag path are trying this on a commercial scale for ag as well. I’ve been following Jay Young for years (YoungRedAngus on YouTube) if you want to learn more about what he’s doing.

Compost is defined by Merrium-Webster as: “a mixture that consists largely of decayed organic matter and is used for fertilizing and conditioning land”. There’s many different methods of making compost and various materials can be used. Gardeners may use materials like vegetable scraps, coffee grounds, egg shells, leaves and grass clippings. Farmers may use materials like manure, straw and hay, deceased animals, leaves, and wood chips. For ag, you may hear terms such as turned compost, windrow compost, Johnson-Su compost…there’s a number of methods that farmers are using to make compost on their farms.

Compost is known to improve soil by adding organic material, nutrients and micronutrients, soil microbes and earthworms. Hundreds to a thousand pounds of compost would be added to ag ground to improve it. Most farmers don’t have that amount nor access to that amount of material.

Thus, the interest in “compost extracts” and “compost teas” in which a small amount of compost (2 lb/ac) is used. The compost is added to water in a tank with a way to agitate it to allow the nutrients and microbes to move into the muddy water solution. For compost extracts, the solution is agitated for 20 minutes to 2 hours (depending on the farmer’s system), filtered, then the liquid is pumped to a tank for the farmer to apply to the field.

We’ve had 7 on-farm research studies in this part of the state using compost extracts as seed treatments, applied in furrow or via foliar application thus far. We kept these studies (other than seed treatment) on the same strips over time. The growers have appreciated “growing their own biological diversity” with costs ranging from $1-6/ac, depending on what else is added. Their desire is to use the extracts to lower nitrogen and other fertilizer use in addition to reducing chemical apps on their farms.

I only have room to share on the compost extract seed treatment for this column. The grower has used compost extracts for years and chose to do a seed treatment study in 2024. The corn had a commercial ShieldCoat seed treatment. He compared that to the ShieldCoat + compost extract seed treatment. This field was impacted by greensnap in July and also Fusarium crown rot. The compost extract seed treatment (215 bu/ac) statistically out-yielded the Check (206 bu/ac). The cost of the compost extract was estimated at $1/ac. There will be another compost extract seed treatment study in 2025. To determine the quality of his compost, the grower sent it in for DNA analysis from Biome Makers and it was microscopically analyzed by Living Soil Compost Lab LLC. This study can be viewed in more detail on page 167 of the 2024 On-Farm Research Results Book.

JenResources 5/11/25

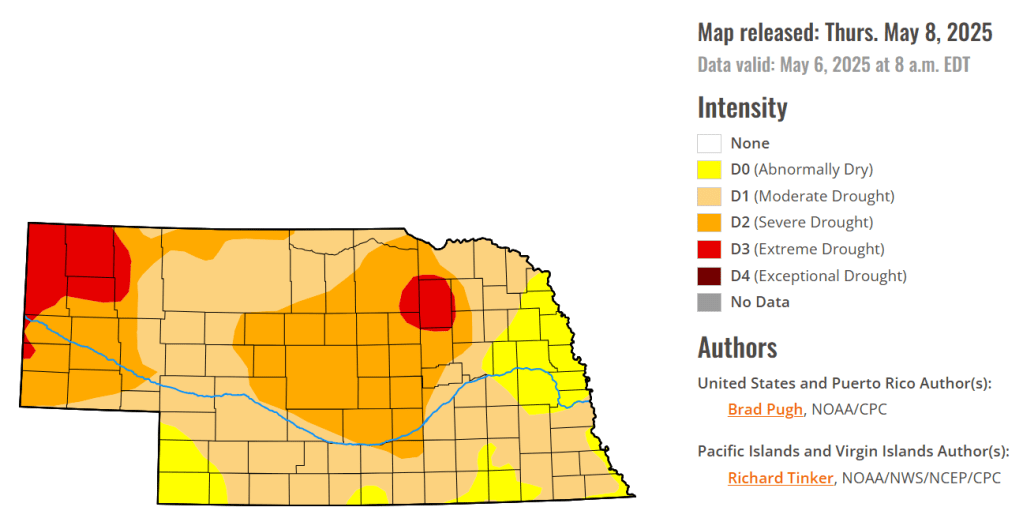

Drought: While it’s sometimes difficult to write a column each week, the record of information on my blog through the years has been of help to me. I was thinking about this spring…how the rye and pastures weren’t growing, and now how the rye and wheat went to head in non-irrigated ground weeks earlier than normal. Why are they heading so early this year? I think it’s because we’ve had such warm soil temperatures coupled with low surface and subsoil moisture in non-irrigated fields. I think the plants are stressed and went into reproductive mode.

I’m concerned that pastures will also be short and head out early too. It’s good to be prepared in the event that livestock producers need additional forage. In mid-April, a Drought Preparation Webinar was held and the recording can be found here: https://go.unl.edu/2025_drought_prep_webinar. There’s also a recent CropWatch article by Aaron Berger, Livestock Educator, sharing the economic tradeoffs of grazing wheat vs. taking it for grain for those with non-irrigated acres that are drought stressed or dealing with virus diseases. You can find the full article here: https://go.unl.edu/mrny.

I know irrigating crops like what is occurring is reminiscent of 2023 in watering crops up and activating herbicide. No one wants the irrigation season to start this early. For curiosity, I pulled the Drought Monitor maps from this week in 2023, 2024, and 2025. 2023 is the year I think of most closely to 2025 so far, even though the drought monitor map in 2023 was much more severe than what 2025 shows. For a planting season, 2025 reminds me more of 2012 with how early everything went into the ground with a warm growing season and no cold snaps. The drought monitor map for the area of the state I serve is similar to 2024, but we also know that mid- to late-May rains changed conditions from dry to too wet in areas north and east of here. Curious as to what year(s) any of you would compare this year to?

Ultimately, we’re not in control of the weather. For the livestock producers in particular, it may be wise to have a forage plan in place in the event that forage resources run short for your operation.

Seed Swap: On a lighter note, we have some interesting on-farm research projects this year! One we’re calling a Seed Swap. This will be my 10th year with the York Co. Corn Grower plot. Any extra seed that we vacuum out of planter boxes is mixed together and planted out. While it’s not a part of the official plot, that area has always beaten the highest yielding number in the plot by 5-10 bu/ac. And, it may not always work this way, but a handful of others also commented they’ve seen something similar. One farmer who had hosted the plot in the past had the idea of trying this via on-farm research. A group of farmers also liked the idea and they all decided on a “seed swap” where they each contributed a hybrid to be mixed together. The mix is compared to each farmer’s hybrid(s) of choice. So in 2025, we’ll have non-GMO and GMO seed swap studies. There’s also a grower who wanted to try this with soybeans, so he has a study combining different maturity groups.

A 2009 study in Ohio compared 5 hybrids vs. mixes of the hybrids. “No significant difference was seen when comparing the yield of a mixed hybrid stand to the average of the two hybrids that were used in the mixed planting. However, there was an observed tendency for the mixed hybrid treatments to out yield their single hybrid counterparts by an average of 4.2 bushel per acre.”

I realize the concept perhaps goes against what many are trying to do with increasing uniformity in fields. My hypothesis in what we’ve seen in the corn grower plot is that the range of maturities (110-120 days) allowed to catch any stragglers for pollination, there was increased diversity in disease/insect packages in combination with more defensive and racehorse hybrids. For those interested in soil health, I also think there’s something to diversity of root structures resulting in more sharing of nutrients and different microbial associations with roots. Those are just hypotheses and we’ll share what we see for results next winter!

Peer Groups

This past week I attended the National Association of County Agricultural Agents meeting in Dallas, TX. It’s a joy to see my ag educator/agent friends serving people through the U.S. and its territories, to talk through local issues, learn from and encourage each other. Extension is truly like a big family, both within Nebraska, and outside of it, and I’m grateful for that and for peer groups in my life over time. Even though I took care of clientele during my time away, it’s also nice to physically get away at times to reset.

A highlight of these meetings is a tour of local ag for that State. My tour was on cotton production including touring a cotton gin. Others of you probably know this, but I didn’t realize the cotton flowers were so beautiful! They begin white when they bloom. Once they pollinate, they turn pink, then turn into the boll which eventually form burs around it. Cotton is either stripped with a stripper header like some harvest wheat (which essentially leaves the stalk standing), or it is harvested by picking where only the bolls are removed. Most of the farmers in this area of Texas use stripper headers. Some fun facts: a cotton boll has 4 compartments, each with 7 seeds in it. Each bale of cotton removed from a field goes through the gin individually. It comes in at about 10-12% moisture and is dried to 6-7% to allow for easier cleaning. The cottonseed, burrs, sticks, etc. are removed from it and the cleaned cotton is baled and bagged with a sticker tracing that bale back to the original field. The grower is paid for the cleaned cotton and the cottonseed (and often more money is made from the cottonseed than the cotton). The rotation in the area I toured was corn/cotton.

(Captions for photos above: Cotton field (top left); Several flower and boll stages in this pic (top right); First flowers are this beautiful white color but don’t smell (bottom left); How cotton comes into the gin compared to cleaned cotton (bottom middle); cottonseed compared to the remaining material removed from the cleaned cotton (bottom right).)

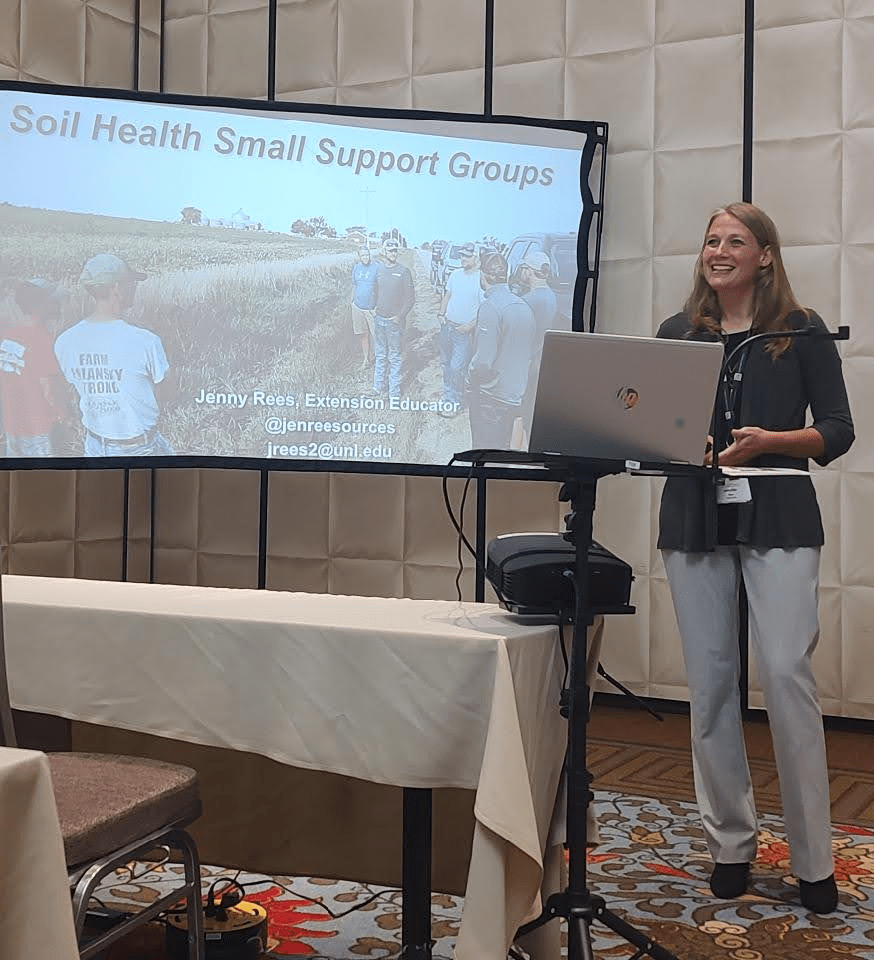

I also presented on the importance of peer groups. Participating in peer groups with like-minded individuals (regardless of one’s career or the topic) is a rewarding way to learn, encourage, and be more innovative. In 2020, in the midst of covid while serving a large area, one grower encouraged me to connect him to the growers I was telling him about who were like-minded in their thinking regarding regenerative agriculture. So, we started a small soil health support group with growers from three counties and myself, met via zoom at first, then did a late summer driving tour of farms. I’ve watched deep friendships develop, sharing of equipment across county lines, and supporting each other’s businesses including cover crop seed sales, biological product sales, seed treatment, and seed cleaning. These specific peer groups have grown to around 30 farmers in a few groups from 6 counties. The goals were connection of like-minded farmers who were humble and vulnerable in sharing successes and failures, openminded in trying new things, and ultimately that collectively we could “fail forward faster” in finding meaningful solutions to reducing chemical and nutrient inputs.

Because the growers wanted to obtain data around some of their efforts, since 2020, they’ve completed 19 Nebraska On-Farm Research Studies in the regenerative ag space. And because farmers like to hear from other farmers, they have shared on these studies at 13 Ag Industry and Extension meetings thus far. In ag, it’s so easy to isolate and feel alone. Perhaps many careers are this way? Would encourage anyone to consider joining or creating a peer group with like-minded individuals if you’re not already in one.

On-Farm Research: I’m so grateful for all the farmers who have/continue to work with me/my peers via on-farm research to collect meaningful data that benefits all of us! The Nebraska Soybean Board followed a few of our farmers with on-farm research efforts last harvest season and had the following short video created that highlights the importance of on-farm research if you’d like to know more: https://youtu.be/XUyouEjYgIU?si=KIVfrXrDR9pSuN_D.

JenREES 3/12/23

Seward County Ag Banquet: The Kiwanis Club of Seward partnered with SCCDP and Seward Co. Ag. Society will honor Seward County Ag Leaders on Monday, March 20, 2023 with the 55th Annual Agriculture Recognition Banquet at the Ag Pavilion at the Seward Co. Fairgrounds. Social hour with wine, cheese, beer, and music will be at 5:30 p.m. with the prime rib meal and program to follow at 6:30 p.m. The cost to attend the banquet is $30.00 per person. Please contact Pam Moravec (402-643-7748) or Shelly Hansen (402-643-3636) to reserve your seat. The Kiwanis Club of Seward will use the proceeds from the event to support the youth of Seward County through a variety of programs and events.

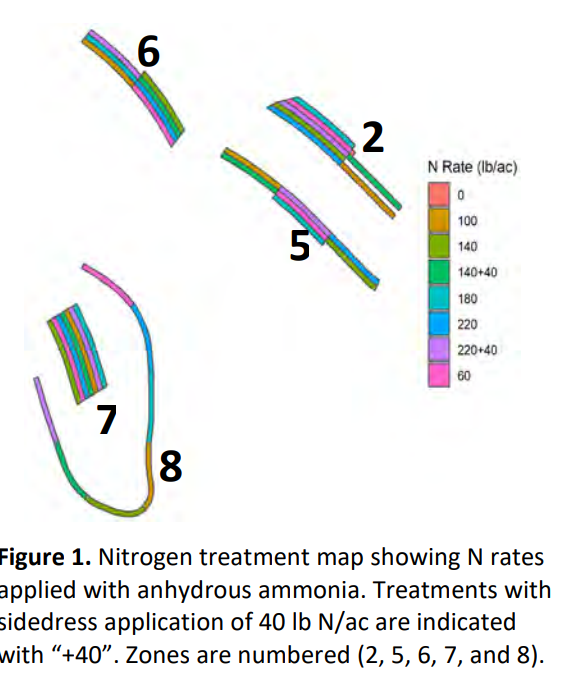

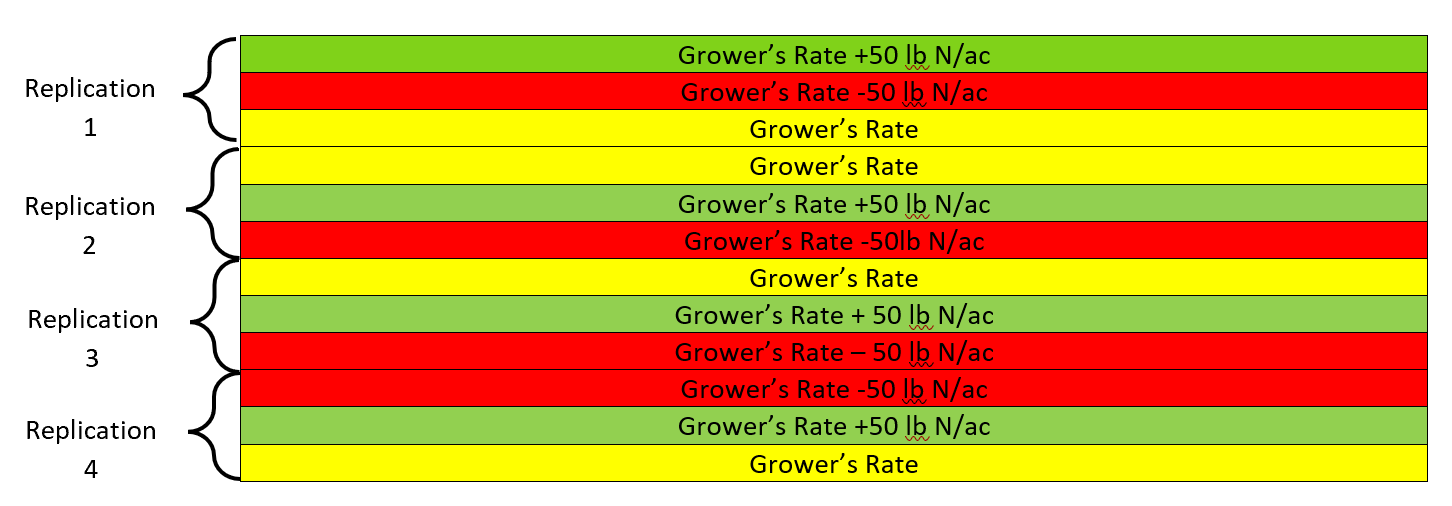

Nitrogen Rate Studies: As growers consider pre-plant nitrogen applications this year, there’s opportunity to consider a variety of nitrogen rates to test any impacts on one’s own field(s). I covered the results of some area studies comparing rates of 50 lb N/ac nitrogen differences in an earlier article. One can easily test this for yourself in a field by either using field-length blocks as those studies did, or with the use of precision ag technologies, prescriptions can be written to try different N rate blocks that are smaller in scale (300’ long by 30’ or so wide). These blocks can then be repeated throughout areas of the field with different soil types and topography. I have an example at jenreesources.com of what this looked like from studies last year. Please let me know if you’re interested in testing this. The 2022 on-farm research results can be viewed at: https://onfarmresearch.unl.edu/.

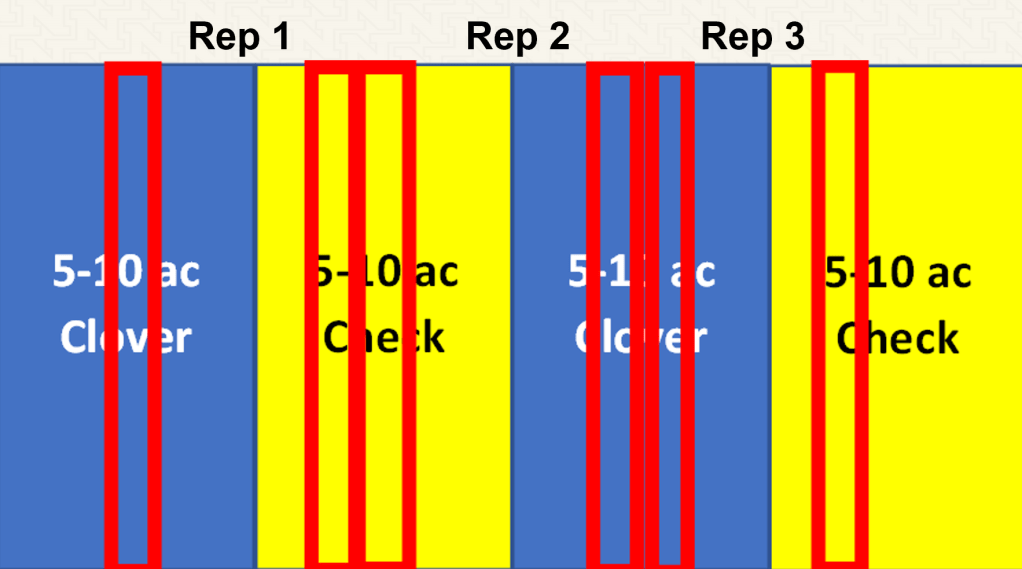

Perennial cover crops: Several weeks ago, I shared our research on interseeding cover crops into early season corn and soybeans and said I’d share our next steps in a future column. One goal of the cooperators was to achieve a living cover that survived into the next growing season. When we saw that interseeded red clover established in soybeans and survived the following spring, we got excited about the possibility of more intentionally growing clovers as a perennial cover crop.

In March of 2022, six sites were dormant seeded with either Mammoth red clover (tall), Medium red clover, or Dutch white clover (low-growing, aggressive like clover in lawns). The clover eventually emerged at all the locations. All but two sites were lost due to the dry spring or June 14 hailstorms. Two sites in Clay County survived the June 7th hailstorm. The grower at those sites chose the Mammoth red clover. It was dormant seeded in March using a drill interseeder into cereal rye. The cereal rye was killed with 10 oz/ac clethodim prior to planting corn and after planting soybean. Once the clover had emerged and was at least 1” tall, Zidua was used in both the corn/clover and soybean/clover areas and was used again 3-4 weeks later. The check areas in the corn and soybean used the grower’s full herbicide program.

The clover provided excellent weed control in the corn. It had good weed control in the soybean with velvetleaf, sunflower, and lambsquarters being the predominant weed species. Biomass samples of the clover prior to harvest showed 30 lb N/ac available. Samples will be taken again this spring. The soybean without clover out-yielded the soybean with clover (74 bu/ac vs. 68 bu/ac). It also economically did better this first year. The ultimate goal is to get something living between the rows for reducing chemical and nitrogen inputs, providing a grazing benefit, and determining impacts to yields and economics over several years. We currently have 9 growers planning on some type of clover study in 2023. If anyone is interested, the easiest way to try this is just dormant seeding this March (can drill or broadcast) clover in 5+ acre blocks leaving a check block between the clover blocks and checks on either side. I will work with you on the combine passes to get the replications. This year the farmers are trying AberLasting clover (Dutch white X Kura), Dutch White + Medium Red, or Mammoth red clover. We also have a couple of growers trying AberLasting with either bluegrass or buffalograss. The simpler design being used by the growers is on my blog. This is a different way of thinking, in some ways going back to what our ancestors did only with today’s hybrids and varieties. These growers are desirous to find ways to reduce inputs on their own farms for the future. Please let me know if you’re interested in trying this too.

The above designs are just some ideas for doing nitrogen rate prescriptions by soil type/topography or field-length strips.

10 lb/ac Mammoth red clover was dormant drill seeded March 2022 into cereal rye. A shot of rain in the spring helped it get established. The grower felt it was more successful establishing the clover into old soybean ground prior to the corn crop. The cereal rye was terminated with clethodim around 10 days prior to corn planting. Once the clover was up 1″, Zidua was applied to the field (other Group 15 herbicides could be used instead). He used Zidua again 3-4 weeks later. The corn with the clover had excellent weed control as did his check treatment which used a full corn herbicide program. The clover got about 2.5′ tall and then laid down. We couldn’t take this study via on-farm research because two different hybrids were used across the clover/check area. He moved over with strip till rig in the fall and took out some of the clover, but quite a bit still remained. Soybeans will be planted in this field next year and the plan is to maintain the clover in the strips without needing to reseed anything.

10 lb/ac Mammoth red clover was dormant drill seeded into cereal rye in March 2022. A timely shot of rain helped with establishment. Soybeans were planted green into the field. The rye was then terminated with 10 oz/ac of clethodim and Zidua was applied when clover was at least 1″ tall (other Group 15 herbicides could be used instead). Zidua was applied again 3-4 weeks later. A June 7, 2022 hailstorm damaged the soybean and clover with the clover recovering faster than the soybean. The Mammoth red clover gets tall and it looked kind of interesting in September to see the soybeans holding the clover up so it could reach sunlight. When soybean leaves started senescing, the clover started forming more of a mat. Primary weed species were velvetleaf, sunflower, lambsquarters (weed species shift from predominantly waterhemp/palmer). This field has a history of being very clean. At harvest, the combine didn’t seem to have much issue harvesting it and the grower had combine set well so there wasn’t green material going into the tank. The field smelled like fresh cut alfalfa after harvest. The grower strip tills in the fall and moved the strip to the side of the old row, taking out some of the clover. Corn will be planted into those strips this spring with the goal of maintaining the clover without seeding any additional clover.

JenREES 3/5/23

Well, March is here, and we start looking towards the next growing season. It was a great winter programming season, though, and it was great seeing many people!

Nontraditional Products: There’s a number of products on the market with claims of the biology or chemistry within them allowing for reduced nutrient inputs by the producer. The goal is for the biology or chemistry to make unavailable nutrients more available to the plant. Interest in the products stems from the potential to reduce nutrient inputs and enhance environmental stewardship, both of which would be beneficial. Perhaps the more recognized products currently are Pivot Bio PROVEN® and PROVEN®40? These products contain an N-fixing bacterial inoculant that is expected to fix N over the growing season. Use of biological N fixation in cereal crops has potential to reduce the use of synthetic N fertilizer, thus increasing N use efficiency and reducing N losses. We have 11 site-years of on-farm research data on the Pivot Bio products in 2021-2022. We have minimal testing on other biological/chemical products for reducing nitrogen rates. Pivot Bio was applied at 12.8 oz/ac and compared to an untreated check. The nitrogen rates were selected by the growers. Some growers chose the same N rate for both treatments, while others chose to evaluate Pivot Bio at additional reduced rates. It’s helpful to see comparisons at a range of reduced nitrogen rates to better determine nitrogen response to products tested.

Across 64 replications, the Check treatment yielded 234 bu/ac on average and Pivot Bio yielded 235 bu/ac on average, with no statistical difference at a 90% confidence level. When looking across the 64 replications, Pivot Bio had a 5 bu/ac or greater yield increase 27% of the time, a 5 bu/ac yield reduction 17% of the time, and yield difference within +/- 5 bu/ac 56% of the time. When looking at many of the individual locations, the grower-chosen N rates most likely could have been reduced beyond 40 lb/ac. Future on-farm research will focus on testing Pivot Bio PROVEN®40 at a wider range of N rates across different soil textures and landscape positions. One way to test this is by creating prescriptions for N rate blocks for different areas of the field. If you’re interested in testing something like this for Pivot Bio or any other non-traditional product, please let me know.

There’s also interest from producers seeking a regenerative ag path to grow their own microbes for reducing inputs through the use of compost extracts and teas. Compost is built through different processes then microbes are extracted from the compost using water and air. The water/microbe solution is then applied to a field while the compost is added back into a pile to be reused. One compost option is via a Johnson-Su bioreactor which uses a static aerobic composting process. Another is aerobic composting via a Turned Compost process. In 2022, a Seward Co. producer chose to compare a Check treatment of 142 lb N/ac and reduce the nitrogen rates added to the biological products in his study by nearly 40 and 100 lb N/ac. His goal was to push the system to see how the biological products compared and to have low enough nitrogen rates to see what the biological products would do in releasing N. His treatments and yields were: Check (total 142 lb N/ac yielding 235 bu/ac); Johnson-Su Compost High (total 106 lb N/ac yielding 220 bu/ac); Johnson Su Compost Low (Total 48 lb N/ac yielding 167 bu/ac); Turned Compost High (Total 106 lb N/ac yielding 212 bu/ac); Turned Compost Low (Total 48 lb N/ac yielding 164 bu/ac); and Pivot Bio Proven®40 (total 106 lb N/ac yielding 195 bu/ac). The Check treatment yielded the greatest and statistically was not different than the Johnson-Su High and Turned Compost High at the 90% confidence level. The Check treatment was different from the Pivot Bio and the lower rates of the compost extracts. The Johnson-Su and Turned Compost were applied at 8 gal/ac extract in furrow at planting. This study was pivot irrigated in a silt loam soil where the previous crop was soybean. This study will continue on these same strips for three years. Please let me know if you’re interested in testing compost extracts as we seek to obtain more data around this topic.

One thing to consider with any type of biological treatment study is it’s helpful to conduct the study on the same areas of the field for multiple years to better determine any impacts over time. 2022 On-Farm research book at: https://onfarmresearch.unl.edu/.

Sensor-Based N Fertigation

Understanding the Soil Microbiome: For those interested, this Friday, March 3, will be our last Friday conversation on ‘understanding the soil microbiome’ at the 4-H Building in York from 10 a.m.-Noon. Dr. Rhae Drijber, UNL soil microbiologist, will kick off our conversation and I’m looking forward to the discussion. If you plan to attend, please let us know at 402-362-5508.

March 4 Gardening Workshop will be held from 10 a.m.-Noon at the 4-H Building in York. Sarah Browning, Extension Educator, will share on vegetable planting basics such as site selection, rotational plan, summer care, and troubleshooting problems such as insects/diseases/weeds. Please bring your questions! This workshop is sponsored by the UBBNRD and Nebraska Extension; there’s no charge and refreshments are provided. No RSVP is required, but it does help with refreshments if you could please let us know at 402-362-6601 or 402-362-5508. If you’re interested in gardening, but don’t have the space at home, check out the Project GROW community garden in York. Plots are available for the 2023 growing season. You can reserve your space now or come to the Gardening Workshop and sign up in person.

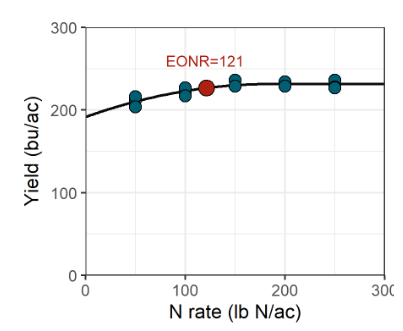

Sensor-Based Nitrogen Fertigation: This week also brings the last of our on-farm research updates (Mar. 1 in North Platte, Mar. 2 in Kearney, and Mar. 3 in Beatrice). You can still sign up at https://go.unl.edu/2023ofr.

One of the most impactful on-farm research studies being shared (I feel) is on sensor-based nitrogen fertigation occurring since 2019. It’s similar in concept to Project Sense, for those of you familiar with sensors being retrofitted on ground rigs for in-season nitrogen applications.

Sensors mounted onto a drone could allow for improved nitrogen use efficiency (NUE) by responding to actual plant needs in season. A grower determined base rate was applied to the field across treatments. Then grower fertigation management was compared to the sensor-based approach in 15 degree sectors on half a pivot. Indicator and reference plots in the field received at least 30 lb/ac less N and 30 lb/ac more N respectively and were established around V7. The field was flown weekly with a drone, imagery was analyzed, and fertigation decisions were made for each treatment sector.

The treatments were: 1) Grower rate 2) Risk averse post-establishment (RAP) (fertigation events applied up to R4 but 30 lb N/ac applied when needed between V9-V14) and 3) Risk averse post-establishment Increased Rate (RAP-IR) (fertigation events applied up to R4 but 60 lb N/ac applied when needed between V9-V14).

Since the beginning of this effort, 100% of the RAP-based sensor treatments were more efficient across all sites than the typical N grower management. Encouraging to me about this method is that it’s all based on what the plant needs after what the soil provides to the plant. There’s no determination of an N rate ahead of time based on plant removal, yield goal, etc.

There were 4 studies in 2022, but I will share on two of them. In a Hall county field with silt loam soils, both sensor based fertigation treatments triggered a total application of 95 lb N/ac vs. grower applying 196 lb N/ac. The grower treatment resulted in a yield of 277 bu/ac at 0.71 lb N/bu NUE. The two sensor based treatments resulted in yields of 271 and 274 bu/ac at only 0.35 lb N/bu NUE! That was pretty incredible for me to see 0.35 NUE and those kind of yields! It shows there is opportunity to consider further reductions in nitrogen applications. At a Saunders county field, no grower rate was used and the beginning base rate was only 33 lb N/ac. The RAP sensor treatment had 108 lb N/ac total applied yielding 258 bu/ac with 0.42 lb N/bu NUE. The RAP-IR sensor treatment had 101 lb N/ac total applied yielding 274 bu/ac with a 0.37 lb N/bu NUE.

You can read more details of this study via the online version of the 2023 On-Farm Research book found at: https://on-farm-research.unl.edu/ (beginning on page 80). For 2023, growers interested in trying this via on-farm research can receive monetary support through a Conservation Innovation Grant to help with purchasing fertigation equipment and/or for the aerial imagery services through Sentinel Fertigation. I would love to see 5 of these in our area of the State this coming year. Please let me or Laura Thompson (laura.thompson@unl.edu) know if you’re interested!

You can still register for the CPIA Conference or walk-in the day of the event. Really practical info. for growers and ag industry!

Nitrogen Rate and Timing Studies

Many farmers are interested in finding ways to grow the same or more bushels with less inputs. Nebraska On-Farm Research has been working with farmers to test different studies, including nutrient management ones, on their farms since the 1990’s. Area on-farm research cooperators and I started the 2022 season with 35 studies, but only 15 made it to harvest with the hail.

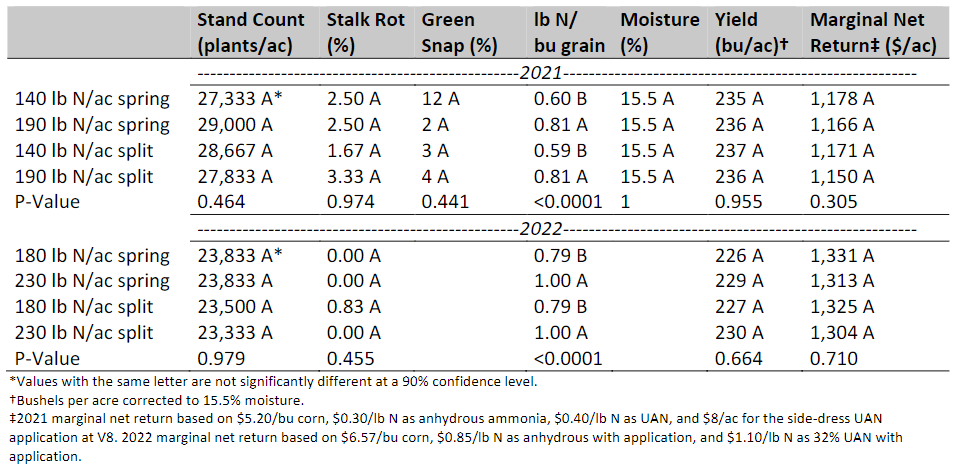

While there’s numerous nutrient management studies throughout Nebraska, I’ll focus on local data. Since 2020, one farmer in the Henderson area has been testing nitrogen rate and timing studies. Fields were impacted by July 9 windstorms in 2020 and 2021 and the June 14 hailstorms in 2022. His goals include testing any benefits (yield and nitrogen carryover) to split applying nitrogen vs. applying it mostly up front, and also testing his nitrogen rate vs. +/- 50 lb N/ac. He’s currently amassed 7 site-years worth of data of which only 3 have shown a difference when reducing his grower rate by 50 lb N/ac. For reference, the soil type is silty clay loam/silt loams and his yield goal is around 240 bu/ac. These studies received partial sponsorship from the Upper Big Blue NRD. All the data is shown in charts at jenreesources.com.

In 2022, his nitrogen timing study was conducted on the same strips as in 2021. This study looked at spring vs. split application of nitrogen at 50 lb rate differences. Treatments were: Spring anhydrous of 180 lb N/ac, Spring anhydrous of 230 lb N/ac, Split 180 (120 lb N as spring anhydrous + 60 lb 32% UAN sidedress), and Split 230 (170 lb N as spring anhydrous + 60 lb as 32% UAN sidedress). The field received 35% hail damage at V5 with harvest stands reduced to around 23,000 plants/ac. Yields from the four treatments listed above respectively: 226, 229, 227, and 230 bu/ac with no yield differences amongst the treatments. In 2021, on the same strips of spring vs. split, treatments of 140 vs. 190 lb N/ac were compared. There again were no yield differences with yields ranging from 235-237 in 2021.

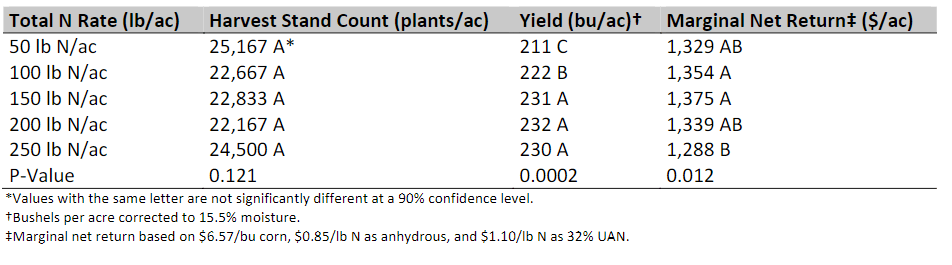

In 2022, he also conducted a study testing the economically optimum nitrogen rate on irrigated corn. The previous crop was soybean and this field had 25% hail damage at V6 on June 14, reducing harvest stands to an average of 23,500 plants/ac. Fall anhydrous in November 2021 was applied at rates of 0, 50, 100, 150, and 200 lb N/ac. All treatments then received a sidedress application of 50 lb N/ac as 32% UAN at V8. The sidedress was surface applied and didn’t get incorporated until a rain 10 days later. 2022 was a high mineralization year, but it’s still incredible to see that with only 50 lb N/ac, he achieved 211 bu/ac! The 100 lb N/ac received 222 bu/ac. There were no yield differences between the 150, 200, 250 lb N/ac treatments with respective yields of 231, 232, and 230 bu/ac. The economically optimal nitrogen rate was determined to be 121 lb N/ac for this field. Studies like this are interesting to show what our farmers are trying. They’re also helpful for examining and rethinking nutrient application rates and timing to our fields. If you’re interested in learning more, would encourage you to RSVP for our on-farm research update held Feb. 15 at the Holthus Convention Center in York at: RSVP: https://go.unl.edu/2023ofr.

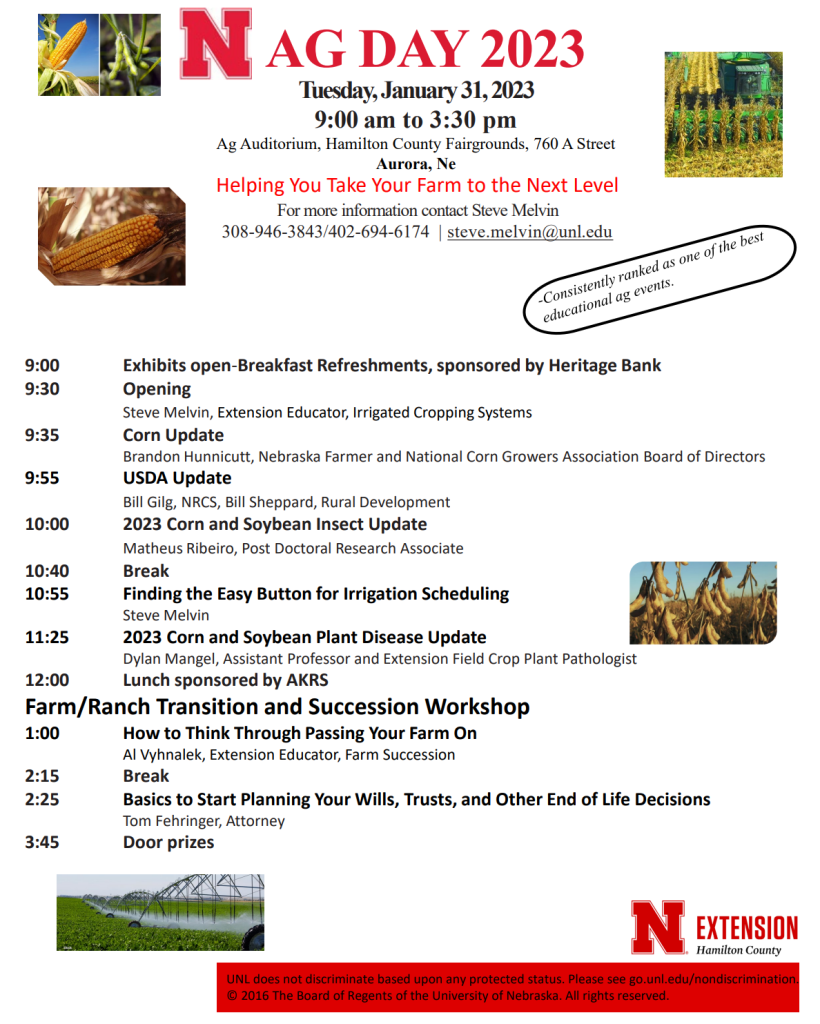

Hamilton Co. Ag Day: Steve Melvin has put together great opportunities for the Hamilton and Merrick Co. Ag Days this year! Jan. 31 is Hamilton Co. Ag Day at Fairgrounds in Aurora with registration at 9 a.m. and program beginning at 9:30 a.m. with Corn and USDA updates. Additional morning topics include corn and soybean insect and disease updates and irrigation scheduling info. Lunch is sponsored by AKRS equipment. The afternoon is focused on a Farm/Ranch Transition Succession Workshop with Al Vyhnalek, UNL Farm succession specialist and Tom Fehringer, Attorney. I’ve heard a lot of farm succession speakers and this duo of Al and Tom is extra helpful. They are so practical and share in a way that is easily understandable and relatable. I could relate to the family stories they shared and have seen some people in tears for two main reasons: wishing they had heard the info. earlier and also grateful they had the info. now to change things for the future. Please consider attending!

2020 York County Spring Anhydrous Nitrogen Rate on Corn

This study essentially showed what the previous studies had: that less nitrogen can be applied without hurting yield or net return. 50 lb/ac N above the grower rate resulted in reduced profit. Field yields were impacted by the July 9, 2020 wind storm. This study is sponsored in part by the UBBNRD.

| Pre-Plant | In-season | lbs N/bu grain | Yield | Marginal Net Return |

| 110 lb N/ac spring NH3 (March) | 25 lb N/ac as UAN May | 0.73 C | 184 A | $599.14 A |

| 160 lb N/ac spring NH3 (March) | 25 lb N/ac as UAN May | 0.98 B | 189 A | $600.38 A |

| 210 lb N/ac spring NH3 (March) | 25 lb N/ac as UAN May | 1.23 A | 191 A | $594.88 A |

2020 Hamilton County Evaluating Nitrogen Rate and Timing on Corn

This study showed no difference in nitrogen timing nor rate on yield and showed less nitrogen can be applied without impacting yield. Yields were impacted by the July 9, 2020 windstorm. This study is sponsored in part by the UBBNRD.

| Pre-Plant | In-season | lbs N/bu grain | Yield | Marginal Net Return |

| 180 lb N/ac Fall NH3 | 25 lb N/ac as UAN May | 1.03 B | 199 A | $629.85 A |

| 230 lb N/ac Fall NH3 | 25 lb N/ac as UAN May | 1.27 A | 201 A | $625.49 A |

| 180 lb N/ac Spring NH3 | 25 lb N/ac as UAN May | 1.02 B | 201 A | $638.30 A |

| 230 lb N/ac Spring NH3 | 25 lb N/ac as UAN May | 1.24 A | 206 A | $641.70 A |

| 120 lb/ac N Spring NH3 | 25 lb N/ac as UAN May 60 lb N/ac side-dress V8 | 1.00 B | 205 A | $645.69 A |

| 170 lb/ac N Spring NH3 | 25 lb N/ac as UAN May 60 lb N/ac side-dress V8 | 1.24 A | 206 A | $633.50 A |

2021 Hamilton County Spring Anhydrous N Rate Study

This study showed no reduction in yield of grower rate vs. 50 lb N/ac under the rate; however, the yield from the -50 lb rate treatment was different from the 50+ rate. There were no differences in marginal net return. This field received 20% wind damage from July 9, 2021 storm. Partially sponsored by UBBNRD.

2021 York County Spring Anhydrous N Rate Study

This study showed no yield difference between the grower rate and 50 lb N/ac over the grower rate but they yielded significantly more than the 50 lb N/ac under treatment and had greater marginal net return. This field received 20% wind damage from July 9, 2021 storm. Study partially sponsored by UBBNRD.

2021 York County Timing by N Rate Study

(Sponsored in part by UBBNRD)

Spring 140 lb/ac: 110 lb/ac N as anhydrous and 30 lb/ac N with herbicide

Spring 190 lb/ac: 160 lb/ac N as anhydrous and 30 lb/ac N with herbicide

Split 140 lb/ac: 50 lb/ac N as anhydrous, 30 lb/ac N with herbicide, and 60 lb/ac N sidedressed at V8

Split 190 lb/ac: 100 lb/ac N as anhydrous, 30 lb/ac N with herbicide, and 60 lb/ac N sidedressed at V8

2022 York County Timing by N Rate Study (same strips as 2021)

(Sponsored in part by UBBNRD)

35% hail damage on June 14, 2022 at V5

Spring 180 lb/ac: 180 lb/ac N as anhydrous

Spring 230 lb/ac: 160 lb/ac N as anhydrous and 30 lb/ac N with herbicide

Split 180 lb/ac: 120 lb/ac N as anhydrous and 60 lb/ac N sidedressed at V8

Split 230 lb/ac: 170 lb/ac N as anhydrous and 60 lb/ac N sidedressed at V8

2022 Economically Optimum Nitrogen Rate

(Sponsored in part by UBBNRD)

25% hail damage on June 14, 2022 at V6

Treatments: Fall anhydrous applied November 2021. Sidedress application of 50 lb N/ac 32% UAN at V8.

50 lb N/ac (0 lb anhydrous, 50 lb sidedress)

100 lb N/ac (50 lb anhydrous, 50 lb sidedress)

150 lb N/ac (100 lb anhydrous, 50 lb sidedress)

200 lb N/ac (150 lb anhydrous, 50 lb sidedress)

250 lb N/ac (200 lb anhydrous, 50 lb sidedress)

2022 Soybean Production Studies

Ag Conference: Thank you to everyone with the York Chamber, Holthus Convention Center, Chamber Ag Committee and Ambassadors, York Visitors Bureau, Sponsors, Vendors, Newspaper and Radio for all their work and help with the York Ag Conference last week! It takes a great team to pull off a successful event. Several individuals were very helpful to me with the pesticide certification trainings; I’m grateful to each of you for your help! Grateful for all the farmers who attended and it was great to catch up with several of you!

Crop Production Clinic Clarification: Both commercial and non-commercial applicators in the ag plant and research and demonstration categories can renew at any of the crop production clinics. The York clinic is reformatted compared to the other clinics, but recertification can be received at any CPC. You can pre-register or walk-in that day for same cost. Info: https://agronomy.unl.edu/cpc.

This week I’ll share on soybean production studies. Our on-farm research update with farmers sharing their results will be Feb. 15 at the Holthus Convention Center in York. Pre-registration at: https://go.unl.edu/3j8q. Grateful for all the cooperators who work with me via on-farm research!

Soybean Seeding Rates: A first-year cooperator from the Utica area chose a soybean seeding rate study of 100,000 vs. 130,000 vs. 160,000 seeds/ac. He planted April 18 with NK 28-T3XF strip-tilled into corn. I started emergence counts May 9 when cotyledons had pulled just above the soil surface. 68% of the 130K, 52% of the 160K, and 48% of the 100K had emerged on Day 1. By Day 9 when I took the last counts, 95% of the 160K, 93% of the 130K, and 94% of the 100K had emerged. The May 22 frost with heavy residue reduced stands in areas of the field down to 35,000 plants/ac. The farmer decided not to replant a large portion of the field including where I had taken these initial emergence counts. This field missed the June 14 hail. The data shared doesn’t include the areas of the field down to 35K. At harvest, 81% of 160K (129,000 plants/ac), 79% of the 130K (103,000 plants/ac), and 86% of the 100K (86,000 plants/ac) remained. There were no yield differences with the 100K yielding 71 bu/ac, 130K yielding 72 bu/ac, and 160K yielding 73 bu/ac. The study results follow 17 years-worth of on-farm research results showing no yield loss when reducing seeding rates of 160-180K down to 120-140K in heavier textured soils. Our Nebraska data also shows that soybean planting rates of 80,000 to 120,000 seeds/ac resulted in the highest profitability.

Soybean Maturity Studies: Seth Naeve, University of Minnesota shared that compared to lower yielding varieties, highest yielding varieties produce between 20 to 40% greater yields. Thus, variety selection is the greatest factor for impacting soybean yield. Third-party information is limited in Nebraska. If there’s interest in a soybean grower plot in the area (particularly someone willing to host this), please let me know. Some third-party resources include: F.I.R.S.T Soybean Testing Program (https://www.firstseedtests.com/), and data from Universities such as Iowa State, K-State, South Dakota State, and Missouri. Seed companies have numerous locations with data. When possible, look at how a variety performs over multiple years at multiple locations.

We now have 13 site-years worth of data from Seward and York counties comparing Group 2 and Group 3 maturity soybeans. Reasons for considering a Group 2 variety in our area include spreading out harvest, opportunity for planting cover crops for greater fall growth, and spreading risk from weather events. In 10 of the 13 site-years, there were no yield differences between high-yielding Group 2 and 3 varieties when planted mid-April to early May. In the other three site-years, the Group 3 varieties had higher yields than the Group 2 varieties. One reason was late season rains benefited Group 3 soybeans in non-irrigated environments in two site-years. In the gravity irrigated ridge-till environment, harvesting the Group 2 variety sooner may have helped reduce plants from lodging down into furrows that are difficult to pick up at harvest.