Using Cover Crops to Help Reduce Other Costs

Fall Armyworms have been around for about 5 weeks now. They’ve really ramped up feeding in pastures, alfalfa, and lawns. Watch fields recently grazed, alfalfa which was recently hayed, and any small grains/cover crops that you are seeding now. Threshold is 3-4 armyworms per square foot but most situations have more. They feed at night and the larger larvae can take out pastures within a day or two. More information at: https://go.unl.edu/oex0.

Using cover crops to reduce other input costs: With an earlier harvest season upon us, tight economics, increasing input costs, and weed resistance issues, the following are considerations for using cover crops to offset and/or reduce other input costs. These considerations come from walking alongside growers who are currently using these practices in their operations at scale and also from research. While adding a cover crop is an additional input cost, look through what I propose below and pencil out the economics for yourself on your own operation. Even if you just try something on one field, it’s worth giving it a try for any of the goals mentioned below.

Forages: Converting some crop ground to annual forages for grazing makes a great deal of economic sense, particularly if you own cattle and crop ground. I will write a separate article on this. For now, rye, triticale, and hairy vetch are options to be considering for spring forage grazing that can be planted yet this fall.

If Planting Soybeans: Goals that fit this consideration: erosion control, weed and disease management. Planting rye this fall or oats in March followed by planting soybeans green into the small grain helps in several ways. First, you can reduce a full PRE-herbicide and only apply the glyphosate at termination time with a residual product if it gets rained or watered in. You should only need 1 POST-herbicide application with a residual product. We have seen rye reduce impacts to soybeans from hail and off-target dicamba. We have seen rye result in no need for a fungicide application for white mold. We have seen oats and rye reduce soybean cyst nematode numbers in fields and reduce sudden death syndrome in fields. There is plenty of research proving how small grains reduce palmer and also soybean diseases.

- For consideration, pencil out removing: Full PRE-herbicide, Second POST-herbicide. With scouting, you can also pencil out removing: Fungicide for white mold. This works best if you plant the soybeans green into the small grain and wait to terminate till closer to flag leaf/boot stage of the small grain.

If Planting Corn: Goals that fit this consideration are: erosion control, weed management, nitrogen from legumes, reducing nitrogen leaching, grazing prior to corn planting. Plant rye, wheat, or winter barley this fall with hairy vetch. Corn can be either planted green into the small grain/vetch mix or the small grain can be terminated pre-plant by glyphosate or clethodim. Don’t use a regular PRE herbicide and allow the vetch to grow till you apply your POST-herbicide that includes an HPPD inhibitor (Callisto-type chemistry to kill the vetch). The vetch will provide nitrogen for the corn crop and an incredible mat for weed control. If one delays corn planting till May 5-15 time-frame, there’s also opportunity to graze the small grain/vetch mix prior to small grain termination and corn planting. While the growers I’ve worked with haven’t observed toxicity from grazing hairy vetch, there are some concerns with this: https://eupdate.agronomy.ksu.edu/article_new/grazing-cover-crops-toxicity-considerations-320.

What one does really depends on the goals. Some are choosing to plant hairy vetch without a small grain to supplement nitrogen. In that case, one needs at least 15 lb/ac vetch seeded preferably in September. If allowed to grow till at least May 10-15 in our area, hairy vetch can provide 50-100 lb nitrogen per acre that we can credit…depending on seeding rate, when it was planted and terminated. Taking a biomass sample next spring will help you determine what potential you have. I highly recommending coupling this with using technology like Sentinel Ag to show when the nitrogen is released to the crop. We had 3 on-farm research studies where corn was planted after hairy vetch in 2025. We don’t have yield results yet, but we did see all three studies show nitrogen release from the vetch around July 2nd. It’s incredible to use tools like this to watch mineralization (or lack of) occur year by year as we just don’t know how to tell this otherwise. Please reach out to me if you’d like to talk through scenarios that may fit your farm goals.

Corn Dry-Down

With harvest ramping up this week, wishing you safety and a good harvest! Make sure to think fire safety and also take care of yourselves emotionally, mentally, and physically. Taking breaks will be important, especially when harvesting this storm-damaged corn, but also because of the stress many are facing.

Watch crop harvest moistures: I mentioned the importance of watching soybean moisture last week and checking soybeans when there’s still some leaves remaining on plants in spite of green stems. We updated this CropWatch article last week https://go.unl.edu/dzb4 and added a table to better visualize what’s being given up in gross by selling soybeans above and under 13% moisture.

Corn is also drying faster than what one may realize, especially after this weekend’s hot temperatures and because of the amount of late-season disease. I’ve been asked what to expect for dry-down for those using storm-damaged corn for high-moisture corn and/or silage. Upon reaching physiological maturity (black layer), most corn hybrids are around 30% moisture. The average corn dry-down for hybrids reaching maturity in late August is around 0.8 percentage point per day and 0.4 percentage point per day for hybrids reaching maturity in mid-September. High heat and wind, such as we experienced last year in September 2024, can lead to well over 1.0 percentage point per day in dry down.

Accelerated senescence and grain drying of corn can also occur with the hail damage and lodging in addition to high amount of late-season southern rust and tar spot this year. One can easily observe hybrid differences in how they’ve reacted to southern rust. Sometimes these pressures lead to premature death of plants including the premature formation of black layer. When that happens, grain drying occurred earlier than anticipated with a higher dry-down rate per day than if the grain had matured normally.

Corn hybrid characteristics can also impact kernel moisture. Hybrids that have thinner or permeable pericarp layers (outermost layer of the corn kernel), are more subject to moisture loss and faster drying rates in the field. I’m unsure how one knows this characteristic though. Other characteristics resulting in quicker dry-down include: lower husk leaf number and thinner husk leaf, how soon the husk leaf tissue turns brown, how well the husk covers the ear (less coverage allows for faster drying), how tight the husk is (as looser husks will increase moisture loss), and how fast the ear turns down vs. remaining upright.

My concern, particularly in the non-irrigated fields, storm damaged stripped up corn, and corn heavily impacted by southern rust in the area I serve, is that corn is actually dryer than one may realize. Apparently this concern also exists in Indiana as Dr. Bob Nielsen, Professor Emeritus from Purdue University, released an article last week on avoiding selling too dry of corn to the elevator: https://www.agry.purdue.edu/ext/corn/news/timeless/WaterShrink.html.

Alfalfa and Wheat Expo: Nebraska Extension is hosting the 2025 Southeast Nebraska Alfalfa & Wheat Expo on Friday, Sept. 19, from 8:30 a.m. to 3:30 p.m. at the Saline County Fairgrounds Office (1600 Tuxedo Park Rd., Crete). This one-day event is designed for wheat and alfalfa producers to gain practical insights, connect with experts, and sharpen their management strategies. Topics include: Equipment considerations for wheat production; Wheat disease updates and management strategies; Insights on achieving high-yield wheat in southeast Nebraska; Alfalfa irrigation, insects, weeds, and crop health management; Pesticide safety updates; Sponsor exhibits, networking, and raffle prizes. Come for the whole day or stop in for the sessions that fit your schedule. Register online at https://go.unl.edu/2025-alfalfa-wheat-expo or call the Saline County Extension office at 402-821-2151.

Harvest Soybean Moisture

What a beautiful September we’ve had thus far! Seed corn harvest has begun and non-irrigated corn is rapidly turning. Soybean harvest will most likely occur by this weekend the way early-season beans are turning.

One note, I’ve noticed droopy ears for several weeks now. It can be due to various environmental X genetic factors such as the high night-time temps coupled with cloudy weather both impacting photosynthesis with specific genetics. I also often observe ear droop to be associated with Fusarium crown rot. Estimated yield losses can be from 12-40% per ear (depending on if the shank pinching occurred during late or early dent stage, respectively). Also, scout fields for shank integrity and seek to prioritize harvest of fields with any increased risk of ear drop.

As we approach soybean harvest, perhaps a frustrating, yet important topic, is seeking to harvest soybeans as close to 13% (the elevator standard) as possible. The frustration is it seems to be such an art and luck in order to do so. For the last several years, it seems that the beans are often drier than what one realizes in spite of green stems and sometimes even leaves remaining on the beans. Test the beans for moisture earlier than you think they may be ready. There’s years like last year when I didn’t even bring this topic up with the hot, dry winds. Hopefully we don’t have a repeat of that.

To avoid beginning harvest when the soybeans are too dry, consider beginning harvest at 14% moisture making combine adjustments and operating at slower speeds as necessary. While there is a dock of around 2.5% for the first 2 points delivering wet beans (the percentage differs by Coops), delivering soybeans much below 13% moisture reduces profits because there’s fewer bushels to sell (load weight divided by 60 lbs/bu assuming 13% moisture). Selling soybeans at 8% moisture, you’re losing about 5.43% yield; at 9% moisture, it’s 4.4%; at 10% moisture, 3.3%; at 11% moisture, 2.25%; and at 12% moisture, it’s 1.14% yield loss. That doesn’t take into account additional risk for shatter losses during harvest. Only 4-5 beans on the ground can add up to a bushel/acre loss due to shatter. The following are profit examples for a field that’s yielding 75 bu/ac:

Example 1. If the grower was to sell beans at 13.8% moisture, he/she could be docked 2.5% of the selling price of $9.60/bu, reducing the actual price to $9.36 per bushel. Total income per acre would be: 75 bu/ac yield x $9.36/bu = $702 per acre gross

Example 2. If the soybeans were harvested at 9% moisture, there would be 3.3 fewer bushels per acre to sell (4.4% of 75 bu/ac yield due to water loss): 75 bu/ac – 3.3 bu/ac =71.7 bu/ac yield x $9.60 = $688.32 per acre gross. In this example it’s better to take a dockage for selling beans at 13.8% moisture than sell them at 9%. The difference is a positive gain of $13.68 per acre or around $1846.80 on a 135 acre field.

Example 3. If the soybeans were harvested at 12% moisture, there would be 0.86 fewer bushels per acre to sell (1.14% of 75 bu/ac due to water loss): 75 bu/ac – 0.86 = 74.14 bu/ac yield X $9.60 = $711.74 per acre gross. If you can’t hit 13%, it’s still pretty profitable to sell them for 12% moisture compared to the other examples.

One more note, we tend to see around 1 day delay in harvest for every 0.1 difference in maturity group. Here’s wishing you a safe and profitable harvest!

Various Resources

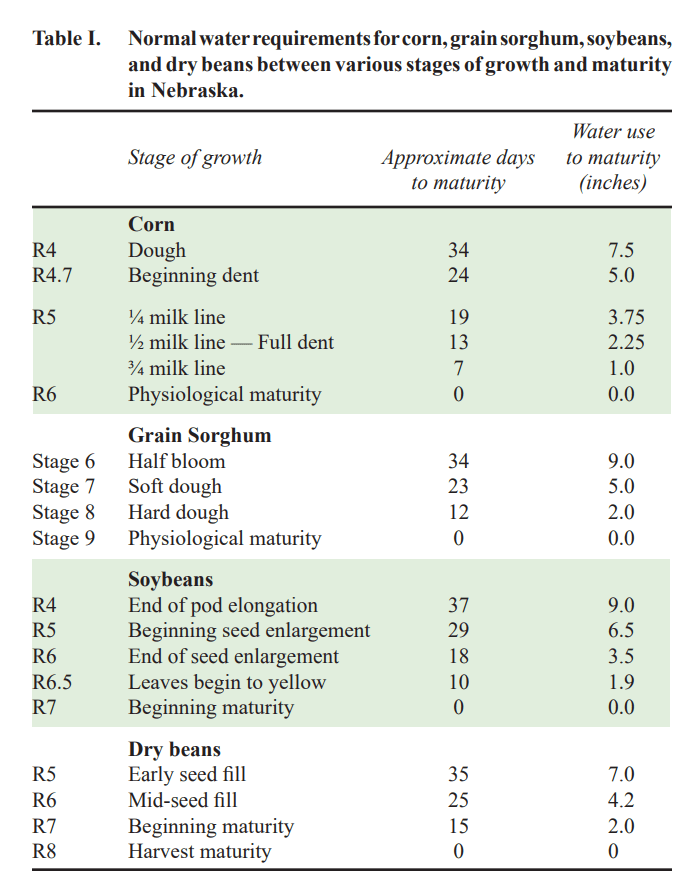

Water use till maturity for Corn: Beginning Dent 5”, ¼ milk 3.75”; ½ milk 2.25”; ¾ milk 1”.

Water use till maturity for Beans: Beg. Seed 6.5”; Full Seed 3.5”; Leaves beg yellow 1.9”.

The Nebraska State Fair is occurring and this past week/weekend was a full one for the 4-H side with FFA projects to be showcased next weekend! Extra special to me are the 4-H identification contests where youth compete to show their knowledge. This year, the York County 4-H youth received Champion Intermediate Horticulture ID team, Champion Intermediate Weed ID team, and Reserve Champion Senior Weed ID Team! So proud of all the youth who competed this year and in the past!

Southern rust of corn was the most frequent question I received last week. The recommendation from research shows there’s no additional benefit to spraying when the corn is two weeks prior to full dent. https://cropprotectionnetwork.org/publications/an-overview-of-southern-rust. Corn is also rapidly progressing in maturity due to the high night-time temperatures we’ve had. This results in corn plants burning sugars at night instead of filling kernels as deeply which can impact yields.

Leaf spot on lilacs: have received a number of calls about lilacs that appear to be “dying”. The culprit is pseudocercospora leaf spot, which is caused by a fungus. The leaves will brown and fall off the lilacs and you will most likely see new growth occurring. Stems are still pliable and buds are still green. Nothing to do other than to rake up the leaves that fall as the fungus can survive in the leaves for two years. More detailed information: https://extension.missouri.edu/media/wysiwyg/Extensiondata/Pro/PlantDiagnosticClinic/Docs/leaf-spot-on-lilac.pdf.

An additional note, fungal leaf spots are found on a number of trees and shrubs right now due to the humid conditions with heavy dew. You may observe impacted leaves fall off early with new growth beginning on the trees/shrubs. Again, nothing to worry about or do for now.

Fall Armyworms have been on the rise over the past few weeks in pastures, alfalfa, lawns, and some crop fields. It will be important to keep watching newly seeded small grain, alfalfa, and cover crop fields this fall. Caterpillars ¾ inch or longer are close to maturity and can be harder to control with an insecticide. There’s a number of conventional and organic insecticides that can be used. Products with 0 day grazing restrictions in pastures include Warrior II, Mustang Max, Beseige, and Prevathon. While it’s not updated, a Q/A for consideration can be found here: https://cropwatch.unl.edu/2021/fall-armyworms-pastures-alfalfa-small-grains-cover-crops-and-lawns/.

Resources: Wanted to share a number of resources. First, a reminder if you have a verbal crop lease you wish to terminate, that must be done by September 1st. More specific information here: https://cap.unl.edu/news/terminating-verbal-farmland-lease-nebraska/. We recommend transitioning verbal leases to written ones and a great resource to help you do that is Ag Lease101 https://aglease101.org/doclib/ where they have various free templates to help.

There have been a number of recent webinars regarding how the Big Beautiful Bill impacts ag. In case you missed them, here’s some recorded webinars:

- Impacts of the Big Beautiful Bill to Ag: https://cap.unl.edu/more-than-one-big-beautiful-impact-ag/

- Changes to Ag Taxes: https://cap.unl.edu/lets-talk-taxes-webinar/

York County Corn Grower Plot Tour and Shrimp Boil will be held September 2, 2025 from 5:30-7:30 p.m. just north of 1603 Road F, Bradshaw, NE. Seed reps will showcase their hybrids, we’ll hear an update from Nebraska Corn, and enjoy a delicious shrimp boil meal (shrimp, sausage, corn, and potatoes). Guess the highest yield without going over and win a $50 gas card. Must be present at the winter Corn Grower Banquet to win. All are welcome! Members are asked to bring a friend and potential member.

Cloudy Days and Corn Tip-Back

Received a number of questions about tip-back in corn and also how the cloudy/smoky days could impact yields. First wanted to mention the difference between pollination concerns vs. tip-back concerns.

Pollination concerns are when the green silk remains attached to the ovule that should have formed a kernel if it had pollinated. Gently husking back an ear and shaking it will reveal where pollination occurred on the ear where the brown silks detach. Green silks remain attached where pollination did not occur. Tip back is when the ovule pollinated but the kernel later aborted (looks shrunken/shriveled) due to some reason, often some type of stress.

This week’s UNL CropWatch shared yield potential for different places in the Midwest using weather modeling and comparing it to a 30-year average. The data clearly shows low solar radiation (which includes photosynthetically active radiation (PAR)), meaning photosynthesis is reduced. In spite of that, the article is suggesting for non-irrigated corn, nearly 100% of above-average yields for the Beatrice area, and nearly 75% chance of above-average yields near the Clay Center and Mead areas. For irrigated corn, it’s estimating 50% near-average yields for Clay Center, 75% near-average yields for Beatrice, and 50% above-average yields for Mead. These estimations are just based on weather and don’t account for stand losses, disease, insects, etc. The full article is at: https://go.unl.edu/tkz6.

Dr. Roger Elmore and Dr. Tom Hoegemeyer wrote a CropWatch article several years ago about the impacts of cloudy days on different stages of corn development. The full article can be found at: https://go.unl.edu/sv06 and the following are excerpts from it.

“Early et al., 1967,…shaded plants around the “reproductive phase” for 21 days as well as during the “vegetative stage” for 54 days and the “maturation phases” for 63 days. Shading during reproductive stages reduced plant yields the most, but 30% shading during the maturation stages ― what we consider the seed set and grain-fill periods (R2-R6) ― not only reduced yield per plant 25% to 30% but also reduced kernels per plant and the amount of protein per plant.

Researchers in a new study shaded plants from silking to maturity (R1-R6) (Yang et al., 2019). They also found reductions in yield and biomass with more shading resulting in more losses. Shading reduced yields more with higher plant populations than with lower populations.”

If you’re seeing tip-back concerns, it could be due to the consecutive days of cloudy skies reducing photosynthesis. But it’s also important to understand the hybrids in your fields. Hybrids are very specific in how they handle stress such as heat, drought, and cloudy weather during and shortly after pollination. Some hybrids have long ears, and in counting kernels, 30-40 kernels per row with a 1-2” tip-back may be “normal”, especially if there are a larger number of rows around for a decent total kernel number per ear. Plant populations also can play a roll in tip-back. So, not all tip-back is a concern. Knowing the hybrid and counting total kernels per ear can tell a bigger story. We will have to wait and see how the remainder of the grain fill season progresses to better understand any potential yield impacts from the cloudy days.

August 2025 Events

Thank you to all who helped make the 2025 York County Fair a success! I didn’t get out to the fields this past week so sharing reminders on some upcoming field days.

Aug. 5 Grazing Cover Crops Field Day of area farmer Alex Daake will be held from 4-6 p.m. at 4136 Superior Rd. near Utica, NE. Alex split a pivot into 4 quarters where he rotates corn, soybeans, rye for seed, and grazed cover crops. The focus will be primarily on what he’s doing for grazing covers and the economics of this system where pasture is limited for cattle production. Alex also has an on-farm research nitrogen study on the corn portion of this pivot where he’s looking at reducing nitrogen inputs due to the grazed cover crops. He’s monitoring the nitrogen strips with Sentinel Fertigation. If you’re interested, you’re welcome to RSVP to jrees2@unl.edu. Walk-ins are also welcome and cookies/water will be provided by Nebraska On-Farm Research.

Aug. 7 South Central Ag Lab Field Day will be held 8:45 a.m.-3:10 p.m. (Registration at 8:30 a.m.) Attendees can tailor their schedule by selecting from various presentations and interactive demonstrations (Irrigation, Diseases, Insects, Weeds (including robotic weeders), Nutrients). There is no charge and CCA credits will be provided. Please RSVP at: go.unl.edu/scalfieldday.

Dan Snow is the keynote speaker and will discuss nitrate challenges in groundwater. This talk will cover findings from a study with the Upper Big Blue NRD and UNL focusing on nitrate and agrichemical levels in the vadose zone across 12 water quality management zones. Lunch talks also feature a farmer panel discussion, providing an opportunity for attendees to engage and interact at the local level.

The SCAL Research Farm is located at 851 Hwy. 6 near Harvard, NE. Directions: 13 miles east of Hastings on Hwy. 6 or 4.5 miles west of the intersection of Hwy. 14 and Hwy. 6 north of Clay Center. Field day GPS coordinates: 40.575256, -98.137824. More info please call (402)762-3536.

Soybean Management Field Days will be held Aug. 12-15. Topics will vary by location and the first three days are twilight tours from 6-8 p.m. There is no charge but registration is requested two days in advance at: https://enreec.unl.edu/soydays/.

- Tuesday, Aug. 12 – Ravenna, NE. Lonnie and Scott Bohn farm 6:00 p.m. to 8:00 p.m. (5:30 p.m. – Registration)

- Wednesday, Aug. 13 – Concord, NE. UNL Haskell Ag Lab 6:00 p.m. to 8:00 p.m. (5:30 p.m. – Registration)

- Thursday, August 14 – Weeping Water, NE, Rick Meyer farm 6:00 p.m. to 8:00 p.m. (5:30 p.m. – Registration)

- Friday, August 15 – Mead, NE, UNL Eastern Nebraska Research, Extension & Education Center – (10:00 a.m. – Registration)

Aug. 25 Regenerative Ag Field Day will feature area farmer Jordan Uldrich. The field day will be from 10 a.m.-Noon, ½ mile east of 1606 County Road J, Geneva, NE. Lunch will be provided following the field day. Jordan has interseeded cover crops into his corn to aid with soil health and weed management. He will also discuss the economics of alternative farming practices. For more information, please call Andrew at 402-590-7096.

JenResources 7/27/25

White Mold in Soybeans Questions: There’s no need to worry about spraying if you don’t have a history of this disease in your fields. If you did have white mold in 2023, there’s potential for it in 2025. There’s also a lot of confusion about what white mold looks like. If one is in a corn/soy rotation, corn residue in a soybean field often has a “white fungal” growth on it this time of year. That’s due to saprophytic fungi doing their job in decaying that organic material; nothing to worry about! There’s also many types of mushrooms that are involved with decaying organic material that one might find in a field. Seeing mushrooms does not mean they’re going to create white mold. The fungus that causes white mold of soybeans creates mushrooms from black sclerotia that look like mouse droppings. When you scout within a soybean canopy, the mushrooms will be attached to the sclerotia on the soil surface. They also have a specific look to them. You can learn more from Dr. Dylan Mangel, Extension Soybean Pathologist, in this CropWatch article: https://go.unl.edu/opv3.

County Fairs: Thanks to all who made the Seward and Fillmore County Fairs a success! This week is the York County Fair; the website that contains the schedule of events and ability to purchase tickets is at: http://www.yorkcountyfair.com/. For those interested in exhibiting items in Open Class, you can find the Fair Book in the Extension Office or online at: https://go.unl.edu/c2qn. Entry times are Tuesday, July 29 from 6-8 p.m. and Wednesday, July 30 from 8-11 a.m.

Testing Moisture in Forages: Dr. Mary Drewnoski sent out the following info. after a summer grazing field day, “accurate moisture testing is key to preventing spoilage and heating in hay and to ensuring proper fermentation in silage. Below are a few options, along with pros and cons:

Koster Moisture Tester

How it works: Uses a small scale and heating unit to determine moisture by weight loss.

Pros: High accuracy (considered the “gold standard”). Works for hay, silage, and other forages.

Cons: Slower process (20–60 minutes per sample). Requires a power source.

More info & instructions: UTIA Publication (PDF)

Where to buy: Koster Tester Website or search online for deals. Price is now around $500 (double a few years ago when I bought mine).

Hay Windrow Moisture Testers

How it works: Dish-style handheld electronic probes for quick readings in windrows or chopped samples.

Pros: Fast and easy to use in the field. Measures a wider range of moisture (13–70%) compared to standard bale probes, making them suitable for silage.

Cons: Less precise than Koster. Can require good sample prep for consistency.

Where to buy: There are mean options on Amazon or a simple google search with this term will give you option. Price range: $200–$400

DIY Option: If you already have a hand held bale probe, here’s a way to adapt it: Progressive Forage Article

Microwave Oven Method

How it works: Drying a forage sample in the microwave to measure weight loss.

Pros: Very low cost (just need a microwave and scale). Works for both hay and silage.

Cons: Time-consuming and requires caution (fire hazard if overheated and results in potential for increased error). Not as convenient for field testing.

Directions: UNL CropWatch Article

Crop Update 7/21/25

Crop Update: Pollination is occurring and with the news on social media, received a number of calls regarding corn tassels this week. Last year, I had seen some “tassel wrapping” in a few hybrids but hadn’t said anything as I didn’t receive calls on it. This year it’s far more widespread throughout the country. What is meant by tassel wrapping is the last few leaves are tightly wrapped around the emerging tassel so that only a small portion of the top is pollinating and showing. As I’ve watched these tassels the past two years, they try hard to emerge from the leaves. Some hybrids are able to push out of the leaves better. Some will push out through the side of the leaves. The tassels then look strange with what parts are able to shed pollen once they emerge from the wrapped leaves.

In some of the hybrids, there’s enough pollen being shed from refuge plants and the tassel tops, that they should still pollinate ok. There’s a few with less pollen shed, yet there’s also corn pollinating in nearby fields. Hopefully there won’t be pollination issues. It will be important to watch your specific fields for pollination.

No one likes to see these things happen. There’s been a number of things shared as to what’s going on. Some are calling this environmental. I’ve heard a number of people talking about either generic dicamba or status applications to corn. I’ve been in the fields looking at this for 10 days and would encourage you to walk into the signed plots of the different companies and local County Corn Grower plots. If this was an environment or dicamba issue alone, entire counties of acres would be impacted because of being in a similar environment and because of how much dicamba is used in post-herbicide applications. This unfortunately appears to be genetic as I’m only seeing it in specific genetics. When across companies, they’re genetically related.

Southern rust was also found in Nebraska last week and in our area, it was found in Butler and Polk counties even though Butler isn’t lit up on the map. It’s at low incidence and not a level to spray yet. I’m still saying to wait till at least milk if you’re still planning on a fungicide app to reduce potential pathogen resistance and for best economic thresholds: https://corn.ipmpipe.org/southerncornrust/.

Summer Grazing Field Day: Alex Daake in the Utica area is hosting a field day on Tuesday, August 5th from 4-6 p.m. at 4136 Superior Rd, Utica. He took a pivot and divided it into quarters. One quarter is soybean, corn, grazed mix for 1 year, grazed mix for 2 years. Cereal rye is also taken for seed after the grazing. He rotates the quarters each year. The field day will primarily focus on how Alex is grazing covers, the cover crop mixes used, and how he feels it’s improving the soil. Come learn about what he’s doing, why, and the economics. On the quarter with corn was 2 years of previous grazing. He has an on-farm research nitrogen study on that ranging from 0-150 lb N/ac. He is also using satellite imagery from Sentinel Nutrient Mangement to determine which plots, if any need additional nitrogen. It will be a great afternoon of learning and sharing! Please RSVP to me at jrees2@unl.edu or 402-440-4739 if you’re interested in attending. Cookies and drinks will be provided.

South Central Ag Lab Field Day will be held Thursday, August 7th near Clay Center from 8:45 a.m.-3:10 p.m. (Reg. 8:30 a.m.). The day is designed so you can pick and choose which topics you’d like to attend. More info. at: https://enreec.unl.edu/south-central-agricultural-laboratory-field-day/.

JenResources 7/14/25

It was a blessing to get away for the national ag agents conference and then on vacation! The keynote speaker was Dwayne Fisher who is the VP Marketing and partner at Champion Produce Sales in Idaho. His speech was about relationships. My takeaway from him was, “The more, more, more is creating less, less, less when it matters most, most, most. When we don’t feel we have time for one more thing, pause and take time to do something for someone else. (Regarding people)-Notice them, Value them, Serve them, Encourage them. We can’t replace Relationships.” This was a helpful reminder and “shot in the arm” for me; hopefully, helpful in some way for you too.

For the ag tour, I learned about wool production and marketing and toured a sheep ranch that was 45 miles from Yellowstone National Park in the mountains. The rancher shared the challenges of grazing thousands of sheep in the mountains with wolves and bears migrating from the park and killing sheep. The specific wolves and bears have to be tracked and ID verified before they can be eliminated. They work with experts to use drone technology and game cameras to help identify the specific animal. At the wool-buying stop, we learned that China dictates the market based on weekly wool sales in Australia. Australia sells more wool in one week than what the U.S. sells in 1 year. The take-home from the wool-buying stop was to buy more natural fibers like wool and cotton.

Fungicides: Received many questions last week on fungicide applications to corn and soybeans. First, tar spot is still at low levels where it’s been found in fields and hasn’t hit the 5-7% thresholds. It prefers temps in the 60’s-70’s, which to me explains why we’ve mostly seen it get worse in fields at the end of the growing season. I realize a lot of fungicide is going on corn. Economically and threshold-wise, I’d wait as long as possible before applying a fungicide. The research from Indiana showed that it was still economical to apply through milk-early dough stage. Waiting will allow for residual for when you may need it later in the season if tar spot or southern rust take off. There won’t be residual left for those making apps now. Just for consideration as the economics don’t justify multiple applications.

For soybeans, if the field had never had white mold in the past, I would not worry about a fungicide for white mold. If it’s a seed corn/soybean or corn/soy rotation field and had white mold in the past, one could aim for one fungicide application at full flower (R2). If you’ve had 2 years of corn followed by beans this year, you probably don’t need a fungicide. And, if you planted soybeans green into a small grain, again, you shouldn’t need a fungicide as we’ve seen small grains keep white mold at bay. I realize I’m more conservative with recs compared to most, but this is based on economic thresholds and understanding the pathogen and crop rotation history. Also, a reminder if you’re interested in using plant nutrition in either corn or soy for on-farm research, please let me know.

Summer Grazing Field Day July 24 will be held at Eastern NE Research & Extension Center near Mead from 9 a.m.-2 p.m. (Registration at 8:30 a.m.). The cost is $20 and they are requesting RSVP for lunch count. More info here: https://beef.unl.edu/news/summer-grazing-field-day-strategies-beat-slump/. The day will be casual and discussion-based. Take a look at the summer phase of a double-crop annual forage system—where warm-season forages like sudangrass (with or without sunnhemp) are being grazed by both cow/calf pairs and stockers. Additional topics include:

- How to manage warm-season annuals to get the most out of them

- What the performance data says (ADG, stocking rate, carrying capacity)

- How the economics compare between cow/calf and stocker systems

- New prussic-acid free sorghum-sudangrass variety

- Virtual fencing in action